October 10, 2020

Offline

OfflineI just got this CBOB a week ago. I don't think it's been shot much and I suspect that I'm the first one to ever open it up. It's a real dandy to shoot, but it gets FTF if freehanded given the strong flip. A full mag of 9 also causes FTF; 8 or less is OK however. I'll change out the potentially worn 22 lb stock recoil spring, or up it to 24 lbs. Should fix what ails it. I've also changed to slotted grip screws (oddly, a bit of a process to do so) and an Ed Brown checkered MSH. I'd have shown the full final product but this site won't upload the file.

Any comments or advice from anyone? It's my first Dan Wesson and I'm absolutely amazed and grateful for the quality of build!

"Knowledge is good". E. Faber

Supporter

Moderators

Dans Club

February 22, 2009

Offline

Offline

DWF Supporters

July 12, 2020

Offline

OfflineExplain the FTF please. Does the slide not return to battery? If it doesn't seem to have been fired too much I wouldn't change the recoil spring. And if your not firing really hot loads I wouldn't go to a 24lb spring it will just unnecessarily beat up the gun and increase the felt recoil. As rwsem said fire it wet.

October 10, 2020

Offline

OfflineHi guys. Thank you for your input.

Off a bench rest I didn't have any FTF issues. When loaded with 9 the slide when dropped wasn't fast enough for the mag spring and the cartridge and slide would get stuck halfway into battery. Free handed (2 hand) muzzle flip is greater than on bench rest so I assumed that due to increased flip the slide was having difficulty getting into battery before the round is stripped off the mag properly. As you state, how could the recoil spring be worn out if it hasn't been shot much? Only theory I have is that in Canada we have to store our pistols with the slide locked back, breech open, mag out and a trigger lock on and in a locked case. If done for any length of time this could have compressed the length and strength of the recoil spring.

To my mind these failures appear to be a result of too quick a mag spring, a worn out recoil spring or both. I got some FP-10 as recommended by DW for break in and I did run it wet when I recently put 200 rounds through it.

"Knowledge is good". E. Faber

DWF Supporters

July 12, 2020

Offline

OfflineI found in mine the extractor tension was a little too much, the case couldn't slide up under it easily and it would hold the round cocked a little which would jam in the chamber. Usually a slight push would put it in battery. Adjusted the extractor tension and now all is well.

October 10, 2020

Offline

OfflineInteresting. I took the extractor out, looking for issues there too, as it does hurl the brass quite far - some 15 feet or more. Upon examination, I found the part to be correctly contoured so I just further polished the necessary places. I checked it for sufficient tension, which it had, but couldn't tell if there was too much tension. Given that the ejection is quite forceful, it might, as you suggest, be prudent to slacken this off a tad. I won't be able to shoot it for 2 weeks yet given my time table but I'll report back then on what I find. Thanks again all.

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineIt has a contoured FPS base as can be seen in these photos. A flat one might ultimately be of help but I gotta go one variable at a time. By the time I get it to the range next

I'll be able to try each change and see what happens. I'll start with the extractor tension, then try a stock 22lb recoil spring, a 24lb and so on.

I'll be able to try each change and see what happens. I'll start with the extractor tension, then try a stock 22lb recoil spring, a 24lb and so on.

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineWow. It seems pretty extreme to have to go to that power level just to get a normal ejection. It's quite far from the factory's best setting of 22lbs. And this is on normal P loads. Do you think the ejector could have any contribution here? It's quite pronounced on these guns, albeit well profiled. Perhaps too long? Maybe if it were shorter the ejection would occur later on when the slide energy has dissipated a bit more?

Most say not to mess with the stock 23lb mainspring (for some reason) but it seems intuitive that if there is an excess of energy in ejecting the brass that this total energy of the slide shooting rearward needs to be mitigated by increased opposing forces via either a higher leverage FPS profile, a heavier recoil spring and a heavier mainspring.

"Knowledge is good". E. Faber

DWF Supporters

July 12, 2020

Offline

OfflineThe heavier recoil spring exerts excessive forward force on the slide and more felt recoil. So unless they are full tilt (or really close) loads this wouldn't be a component I would change. Factory loads should be fine with a 20lb or 22lb recoil. I had two very good smiths tell me that they would have recommended the 28lb mainspring with a 20/22 lb recoil. With that set up it doesn't beat up the slide and frame like the recoil can and it keeps the felt recoil down.

October 10, 2020

Offline

OfflineSome damn good points you make. I guess I overlooked the damaging effects of the vector of force supplied directly to the frame by the 2 way power of the recoil spring. I guess most are reluctant to increase mainspring force first as it can increase trigger pull. In light of these interactions (increased battering of the gun and potentially heavier trigger pull) it might be wisest yet to go straight to the square FPS to see where that leads first. And what an easy fix that would be for starters.

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineI think in light of the excellent points made above, I will start with replacing the stock 22lb recoil spring with a fresh stock spring of the same rate and add in the squared off profile FPS. I think if brass with factory loads is ejected only 10 feet at that point its probably a good compromise to stay with.

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineGenius. Never occurred to me 'til now. The gun would then legally compliant without trashing the recoil spring when stored. I've never had to use the bushing wrench so this will be an easy task going forward. BTW, in Canada we don't have SD guns, just paper punchers!

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineHoly smokes. If anyone is following this thread, standby til tomorrow when I can add more photos. The problem is with the extractor. It's way too long such that the cartridge has to ride overtop of the protruding claw to get to the breech centre. Once there the cartridge face is probably a full third of a millimetre high-centering on the extractor claw off of the breech face!. It's too far out of whack to fix this extractor. Also the ejector tip is angled down. I've ordered a new Ed Brown extractor, a new extended ejector and an oversized flat bottom FPS so I can smith the entire system. Wow. I just assumed the extractor just needed tuning.

"Knowledge is good". E. Faber

October 10, 2020

Offline

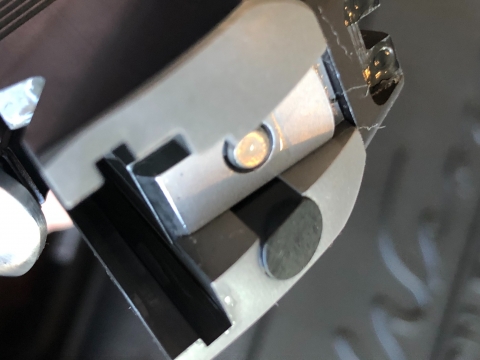

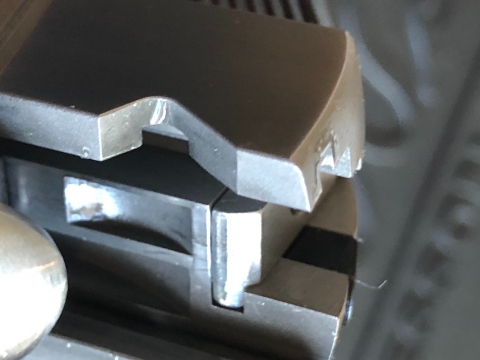

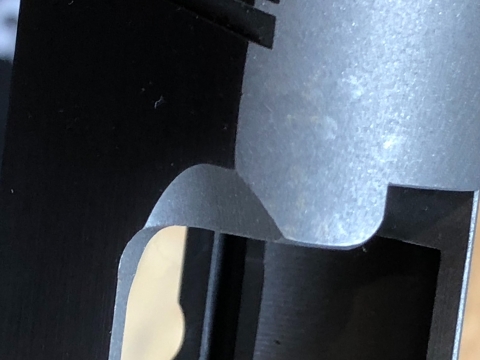

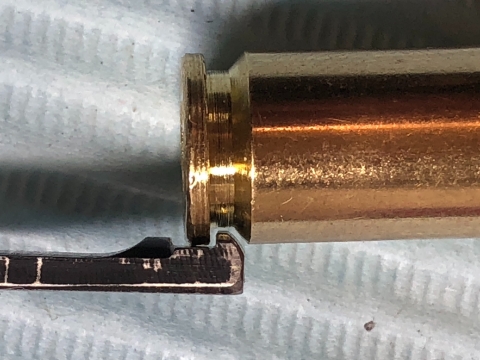

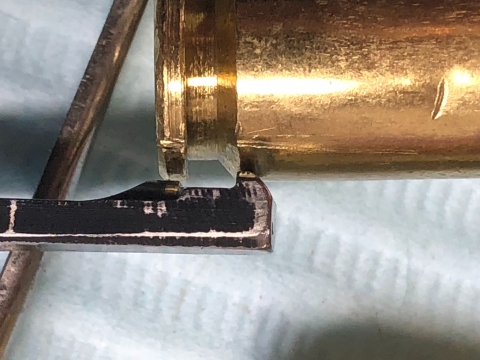

OfflineThese are some photos. The extractor protrudes too far forward. As said above, the cartridge as it moves up from the mag high centres on the top of the claw and the is held there up to 1mm off of breech face. Note the gouges on the brass rim and body. Note brass hits on slide. Note off centre firing pin strike. Note lack of breech face marks. As can be seen also that the extractor would have fit if it was protruded about 2-3mm less forward.

Note also the shape of the ejector, angling downward. Forget clocking etc, this extractor is getting replaced first with the square bottom FPS. The ejector I'll sort out later.

I'll get more photos with the new extractor and FPS in place then do a range report.

I'll get more photos with the new extractor and FPS in place then do a range report.

"Knowledge is good". E. Faber

1 Guest(s)

Register

Register Log In

Log In Home

Home