October 10, 2020

Offline

OfflineYeah, its a messed up situation. Goes to show you, however, that any new-to-you gun should be thoroughly inspected before use. ,

I guess I made the mistake of assuming that since this gun was so pristine and unadulterated, that it would be good to go. I can't imagine that this gun would have come from the factory like this. Perhaps someone put in a new extractor, wrongly assuming that all 1911's be they government, commander, 45, 9 or 10mm are the same?

Once I get the new extractor I'll compare it with the current one which, should be interesting. It's amazing that this gun worked at all!

"Knowledge is good". E. Faber

DWF Supporters

July 12, 2020

Offline

OfflineYou are right on all points. And the ejector looks like it could easily set off a live round if you had to clear one, definitely a change there is needed. None of my 10's are pointed in that manner. The ejector is a little harder on the smithing scale unless you have the tool to help in staking them.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineOctober 10, 2020

Offline

OfflineJesus. I never knew that an ejector could fire a round. Always keep the muzzle pointed down range! Since this gun jams a lot I've had to clear many live rounds. I'll try to find out what the factory ejector profile looks like - for all I know that part too could be compromised. I've changed an ejector on a Colt Gov't 1911. The pin was a pain but the ejector itself wasn't staked. Is DW CBOB, or commanders in general, different?

To SOWELA, I do run this gun wet with FP-10 as DW recommends. In that vein all is good - no galling on the slide so far and no further issues (other than those mentioned) as the gun heated up. Are you able to send a picture of a round on the breech face and of the ejector profile? PM-10 should be a really good comparison.

Thanks guys - really helpful advice on this unusual issue!

"Knowledge is good". E. Faber

DWF Supporters

July 12, 2020

Offline

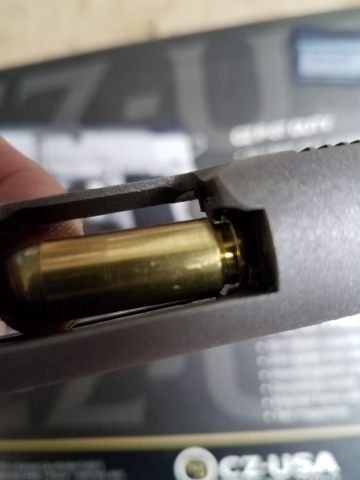

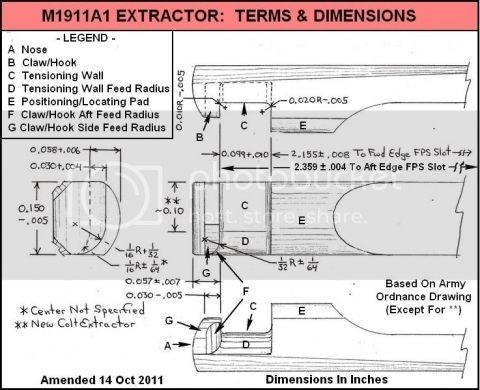

OfflineFrom what I've been reading the case is supposed to have a small gap in between itself and the breech face. There should be .075-.085 between inside of hook to the breech face, .075 being optimal. Extractors can vary in length between manufacturers and vary in length depending on amount of deflection. I think it was also stated that the .45acp extractors are a tad longer so if you change it get one for a 9/.38/.40.

October 10, 2020

Offline

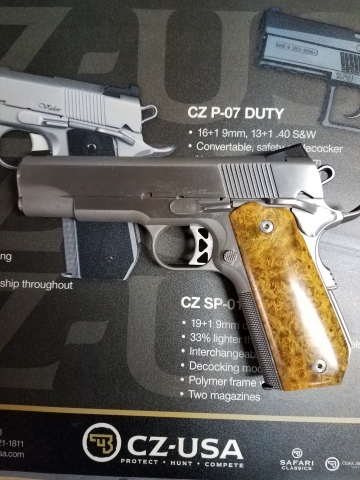

OfflineThanks for the photos they are a big help. Nice gun BTW (amboyna burl?). Thats a very different ejector profile from mine. I'm trying to search around for the DW factory ejector so I can make sense of my situation. So far, almost every shape and length is in use which adds to the confusion and frustration. I suspect that I have a 45 ejector in mine given how wrong the size is. This order by mail business is quite frustrating as its usually a 2 week delay from Brownell's and most of the parts from elsewhere won't ship to Canada, even though for small stuff they legally can. I've got an oversized FPS, a new ejector and new extractor coming.

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineSoooo that was a long wait to get the parts needed - Ed Brown extractor for 10 mm 1911, EGW oversized FPS and Nighthawk ejector. Total $92 USD.

Last night I started with the new extractor. When compared side by side with my original extractor (the one too long, tailpiece jutting out, claw point touching above the cartridge bevel, etc.) much to my horror, they were identical!! WTF?

After a lot of cussing/pacing then figuring, I elected to fit the new FPS first What a chore that was as it was oversized in every dimension. It is now just snug, positive and centred on the firing pin.

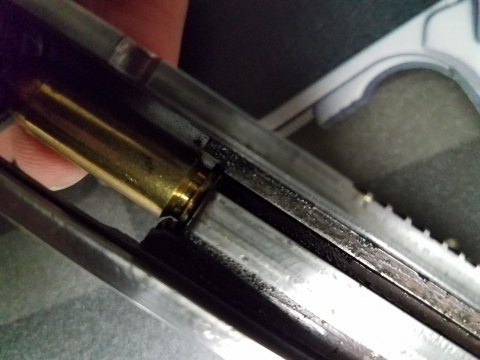

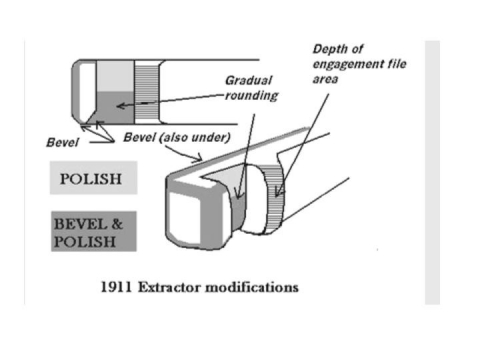

The extractor length I couldn't solve by adjusting the claw shape alone as with the amount needed it would end up but a blunt nub. The only way I found to shorten it was to enlarge the slot for the FPS by filing the forward most surface of the slot thus when the extractor is drawn backwards, less of it protrudes into the breech. (More of it now sticks out the back of the gun!) Then with the proper protrusion, the claw dimensions and tension could be set. The trick was to ensure there was adequate tension on the extractor at all times, then proceed to adjust the locating pad the get the claw to sit properly in the cartridge up against the breech face. Then I fine tuned the claw dimensions. This took considerable time and I'm a bit choked because the resulting claw hook itself is a bit thin and therefore fragile. But what else could I do? Hope it lasts.

Satisfied with the tension and arrangement of the installed extractor (barely holds a live round when shaken) there was almost 2mm stick out. Yikes. Too chicken to file this down when in place, I instead went with the remove/file/reinstall journey to avoid that one mistake injury to the rear of the slide. By blackening with a Sharpie then filing where needed, it approached being flush and I was able to get a pretty damn good final fit. I cold blued when done. Looks like nothing was ever changed!

Upon initial test ejections with snap caps, things seem pretty comparable with my tuned Colt Government. Ejects consistently to 4 o'clock on the right trajectory. Hallefuckinlujah to that! Next is a range test.

As far as the ejector goes, first things first. Agreed that the original it is quite long, the new NightHawk one is both much shorter and flat nosed. I'll see how live fire tests go. I can always alter the original at the range first before an outright change there. I'll check in then. Pictures to follow.

"Knowledge is good". E. Faber

DWF Supporters

July 12, 2020

Offline

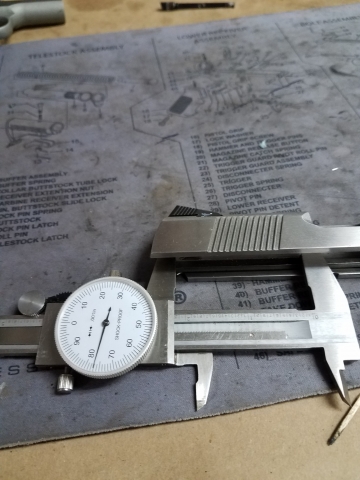

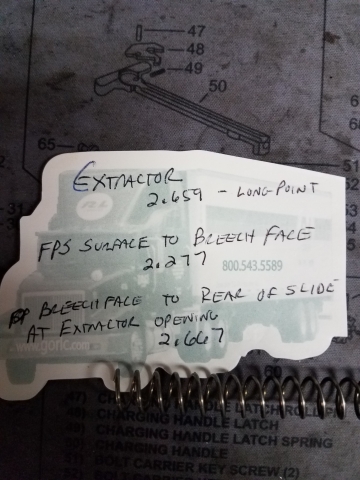

OfflineOk I went and did some measurements on mine. Some may not be needed but I figured for comparison sake just in case of machining/fitting differences.

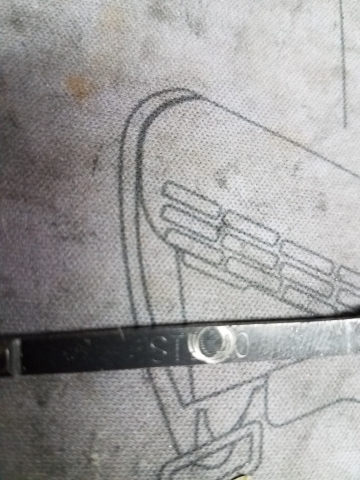

Just tying to figure why your extractor sticks so far out the back. The hook problems out front were most likely because of it being for a .45acp. 10mm, 40SW, .38Super and 9mm are a different extractor. If you can see on the side of my extractor it is stamped STD 40.

October 10, 2020

Offline

OfflineThis is getting weird. I double checked the EB part and sure enough it's #1300 extractor for 10mm. Maybe a slip up in packaging? An extractor from a 45 ought to be bigger but I saw some YouTube videos that claim it to be the same as 10mm while 9mm is much smaller. I then looked up EGW and they list a single extractor for 9/38/40/10mm, and another for 45. I suppose the answer is to order a different extractor altogether as the odds of 3 now being mislabeled is pretty low.

I suppose it is likely that the original extractor was replaced with one for a 45 then it had significant FTF and FTE episodes, so, frustrated, the owner shelved it for years, then sold. Ten mm 1911's aren't common so it's entirely possible that 45 is subbed in for a bona fide 10mm extractor. I guess I'll be back once I've been to the range

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineUpdate: I forgot to mention that the reason for changing out a perfectly good FPS is that the new EGW FPS is a square bottom intended to slow the slide quicker before ejection, and therefore limit how far casings are hucked.

Also, thanks 605DART for the trouble you took to measure and photograph your gun. A big help once I work up the nerve to tinker with my CBOB again.

Lastly, I was able to order an STI Extractor for 38/40 (and 10mm). This one comes stamped in big gold letters "STI 38/40". Fingers crossed!

"Knowledge is good". E. Faber

March 21, 2010

Offline

OfflineEGW flat bottom firing pin stop, 25# mainspring & 18# recoil spring is what I have found works best in the commander 10mm pistols.

Empties are ejected @ 6 feet to the right. Muzzle flip greatly reduced.

45 or 9mm extractors can either be used, 9mm doesn't need profiling in my experience, but 45 can be made to work. In fact I think that 45 is what pistolsmith Don Williams uses in his 10mm builds.

Best thing for these guns is shoot them wet for the first 1,000 rounds. They were built really tight. After that, most problems seems to disappear.

October 10, 2020

Offline

OfflineHey thanks El Hombre. I've got new recoil springs on the way in case I need them. I think stock is 22# but 24# is also popular and I have both on the way. I've also read that the main spring needs to be Officer-sized due to the bobtail, but first things first.

As far as the extractor saga goes, I finally got the new STI extractor I ordered last month. This one is stamped "STI 38/40", but when compared with the original one and the previous new one THEY ARE ALL EXACTLY THE SAME! Same length, slots etc. Identical. That means that if I install the newest one I would need fit the hook extensively, the FPS slot and fix the extended stick out at he back of the slide just like I did before.

So, WTF? I guess I'll just stick with the one that's now in the gun since I've got about 4 hours into it. I'll test fire it tomorrow or the next day and I'll take notes to report back here. So far, it's able to shuck snap caps to the right landing zone but we'll see with live fire. Sucks that I had to spend all this time and money to discover this the hard way. Hopefully some one out there can learn from this!

I have only 2 questions left:

1) Do you think Dan Wesson would have put such an extractor in at the factory?

2) Or, do you think the original owner had extraction issues, changed out the extractor with an after market one, continued to have extraction problems, got frustrated (sound familiar?) and put the gun away for a decade, only to end up selling it in the end?

"Knowledge is good". E. Faber

October 10, 2020

Offline

OfflineWell, I got all of the measurements I needed, short of taking the whole gun apart. But it turns out they're absolutely meaningless. All that really matters, it seems, is that different manufacturers make different length extractors, ejectors and firing pin stops and the only question is "can you make the ones you've got fit your gun? And then tune them?"

I read that currently there are over 20 manufacturers of 1911 extractor. Some makes are known to be shorter on some guns and others to be longer on other guns. But they don't say which are on which and due to the phenomenon of "tolerance stacking" its often a best guess scenario.

This problem, although new to me, has references going back to early 2000's on most 1911-geared websites. The "Extractor/Ejector/FPS Complex" (EEF Complex) as it must be considered, is a 3-part interacting complex wherein all 3 parts collectively affect feeding, extraction and ejection; and hence, reliability, manifesting as jams, stovepipes, FTF, FTE, FTRB, FTLOLR and so on.

From all this research and trial and error, there are several lessons to be learned about the 1911 EEF Complex. Ultimately, one should simply buy an extractor that has no FPS slot at all, allowing you to cut your own FPS slot to size and fore/aft location. EGW and Harrison make these for all calibers in blue and SS.

Whenever any new part or parts of the 1911 EEF Complex must be changed, one should follow the steps below to get the best results possible.

1) Try to SEARCH forums for a brand of extractor/ejector/FPS known to have worked in your gun brand and caliber.

2) Fit the GEOMETRY of the hook end of the extractor to how it is supposed to fit the brass rim of the casing of your particular caliber.

3) ESTABLISH the hook-to-breech face distance necessary for your gun's caliber, e.g., 0.065", 0.075 "etc.

4) Mark and cut your extractor's FPS POSITION to produce this above level of protrusion (hook-to-breech face dimension).

5) Adjust the extractor DEFLECTION by altering the extractor's positioning pad thickness - eg., 0.010" or less, etc.

6) Adjust the TENSION of the extractor by doing the "loaded cartridge test".

7) Check EJECTOR LENGTH for your caliber such that it is long enough to eject live rounds by hand. (ie, 45's are short, 10mm's are long)

8) TEST your ejection PATTERN at the range with live rounds for distance, placement and consistency; alter ejector nose geometry as needed. If distance is too great, consider reducing the slide's rearward SPEED by changing to a flat end FPS. (EGW makes a dandy.)

9) Once happy, SHAPE the rear extension of the extractor so that it is flush with the rear of the slide - after all this, 'might as well make it look good!

"Knowledge is good". E. Faber

DWF Supporters

July 12, 2020

Offline

OfflineMan, my fingers hurt just looking at all that typing! LOL

I'm sure that is the most proper way to go if your a 'smith and/or have the skills, machinery, tools to make one from a blank. But most who replace a extractor do so with a mostly drop in part that may need some minor hook work and a new FPS install to make it register correctly. I've never seen one that hung out the back like that or had the hook so far out of spec from the breech face and in it's contour. Plus this was with two new extractors (I think) you had to purchase, that's what made me think the slide dimensions could be off some. Well I hope you can get your 'bob' running reliably as they are wonderful gats when they function as good as they look. Please keep us updated with what changes/work you do on this and which changes made a difference. I always like to learn something .

1 Guest(s)

Register

Register Log In

Log In Home

Home