Dans Club

January 17, 2015

Offline

OfflineI have placed a deposit on a .357 Super Magnum, I am going to inspect it in the next few days to check condition. In the meantime, I am trying to read more about the calibre and see what I may need for reloading.

I can find .357 Max brass up here easy enough, though it appears .357 Super Mag I will need to import. So for those that reload this calibre, I have a few questions:

* can I use my current .357 dies for both the Max and Super Mag brass?

* I generally use Titegroup, but does anyone have a preferred load for their .357 Super?

* can I just use .357 Max brass with similar loads?

* where do you find the heavier bullets? 158g is all I can find thus far.

Other than the closer barrel gap, are there other tips you can pass along, please?

I know, I know - pics. I want to check the top strap condition, hard to tell from that pic if it is damaged. Is this something I should walk away at a certain point? And welcome to Canadian pricing.

Thanks. Ian

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

OfflineI use the Max brass and loads. You can use what ever powder you have data for. Finding the heavier bullets could be the difficulty. You will find a flame cut on the strap if the gun was fired, but it will only be a few thousandths deep, it self limited and was not a concern unless someone fired a ton of hot, light loads.

Anything worth doing is worth doing well.

My father

If a man designed it, and a man built it, then a man can fix it.

My grandfather

Dans Club

January 17, 2015

Offline

OfflineSCORPIO said

I use the Max brass and loads. You can use what ever powder you have data for. Finding the heavier bullets could be the difficulty. You will find a flame cut on the strap if the gun was fired, but it will only be a few thousandths deep, it self limited and was not a concern unless someone fired a ton of hot, light loads.

I just got off the phone with a guy I know that owns a small online reloading shop. He can get me both 180g and 200g bullets from a variety of suppliers. I am leaning towards the gas checked hard cast either Cast Performance or Double Tap bullets. Is being gas checked important to stop lead build-up on the cone?

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

OfflineMarch 19, 2016

Offline

OfflineThe gas check question is easy. They do not hurt anything if you use them. There are a few variables that determine the need for gas checks. Hardness of lead, fast or slow burning powder (they differ in temp) and the velocity you are pushing the bullet out of the barrel. You have the option of lead, plated, and jacketed bullets. So if you have problems there are options. If you are going to use lead you may want to slug the barrel so you have some idea what bullet diameter you should be looking for. Too small of diameter lead bullet will also cause leading in barrels. I would say go over the barrel diameter by a .0001. I ran gas checks anytime I was over 1200fps. I was using wheel weight lead at the time. There are some very good bullet lubes for cast bullets now and some guys powder coat lead bullets so they do not have to mess with bullet lube. My biggest concern was not lead on the cone, it was a hot load melting the base of the bullet. The bullet base needs to make a good seal for the powder charge behind the bullet to be consistent. Gas checks of course will provide a good seal and protect the bullets base. The gas check also cleans out any lead left in the barrel by the bullet. I myself would look for 180-200 grain plated bullets. I hope I did not make this sound complicated. Have fun with figuring it out, that is what it is all about. I do not shoot a 357 Supermag. I shoot a 445 Supermag. The are both great guns. Maybe some day I will have both. Good luck

Dans Club

January 17, 2015

Offline

Offline10magnums said

The gas check question is easy. They do not hurt anything if you use them. There are a few variables that determine the need for gas checks. Hardness of lead, fast or slow burning powder (they differ in temp) and the velocity you are pushing the bullet out of the barrel. You have the option of lead, plated, and jacketed bullets. So if you have problems there are options. If you are going to use lead you may want to slug the barrel so you have some idea what bullet diameter you should be looking for. Too small of diameter lead bullet will also cause leading in barrels. I would say go over the barrel diameter by a .0001. I ran gas checks anytime I was over 1200fps. I was using wheel weight lead at the time. There are some very good bullet lubes for cast bullets now and some guys powder coat lead bullets so they do not have to mess with bullet lube. My biggest concern was not lead on the cone, it was a hot load melting the base of the bullet. The bullet base needs to make a good seal for the powder charge behind the bullet to be consistent. Gas checks of course will provide a good seal and protect the bullets base. The gas check also cleans out any lead left in the barrel by the bullet. I myself would look for 180-200 grain plated bullets. I hope I did not make this sound complicated. Have fun with figuring it out, that is what it is all about. I do not shoot a 357 Supermag. I shoot a 445 Supermag. The are both great guns. Maybe some day I will have both. Good luck

You aren't making it complicated at all, this is the exact info I was wanting to see; thank you. I prefer plated bullets in my longer barrels for my 15-2s, but the only option I was given from the one shop that deals with many suppliers for the Super Mag were 180g plated HP bullets to the tune of $35 per 100. I'll call a few more places once I have the SM in my hands.

I take it that this SM is a large frame and therefore none of my 15-2 grips will work with it, correct?

Supporter

Dans Club

DWF Supporters

February 4, 2017

Offline

Offline

DWF Supporters

April 9, 2015

Offline

Offlinehttp://missouribullet.com/details.php?prodId=214&category=5&secondary=10&keywords=

Missouri Bullets has a 180 grain Hi-Tek coated. I have been replacing all of my Hardcast lubed bullets with Hi-Tek coated bullets. They produce much less smoke and I have not seen any leading of the barrel or cone while using them. For the price this is what I will be buying as soon as I shoot up or sell my remaining Hardcast Lubed 180 grain bullets.

I have never used gas checks so I am not knowledgeable about their use. If I felt a need to use them or read more about them I would but the Hi-Tek coating and the price of these bullets takes care on my 357 Super Mag reloading needs.

“We cannot but pity the boy who has never fired a gun; he is no more

humane, while his education has been sadly neglected.”

-Henry David Thoreau

“When some of my friends have asked me anxiously about their boys, whether

they should let them hunt, I have answered, yes – remembering that it was

one of the best parts of my education – *make* them hunters.”

-Henry David Thoreau

March 28, 2019

Offline

OfflineSo far I've used Vihtavuori N-120, Accurate AA-1680, and Lil'Gun following the loading guide on Ammoguide.

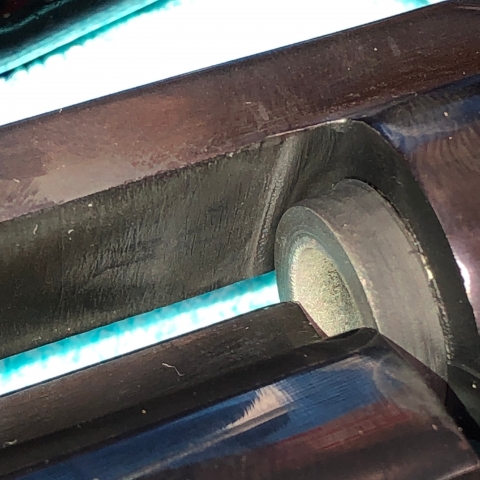

Now that I've been to the range I can definitely say that flame cutting can occur with hot loads and 158 and 180 gn bullets. In particular I used Vihtavuori N-120 at 25.5 gn with 180gn Hornady JHP (1930 ft/s and 1490 ft-lbs) and got aggressive flame cutting. Fortunately I didn't shoot too many rounds so it's not too deep.

I plan to epoxy a pice of 0.1mm Tungsten shielding onto the top strap to see if that provides protection. Maybe someone else has tried this?

September 16, 2008

Offline

OfflineI know this is old, but some of the answers, or lack thereof, surprise me.

.357 Maximum, .357 Super Mag = same caliber. Super Mag was the original Elgin Gates name and DW was tight with silhouette and Elgin so they used that name instead of the Ruger/Remington SAAMI name.

Any .357 dies can be used, but older dies sets may not allow full sizing and/or seating on Max/Super Mag cases. OD and ID is the same. The length is the difference.

Flame cutting was shown to be mostly caused by ball powders and light bullets. Feed it heavy bullets and stick powders and all is good.

Dans Club

January 17, 2015

Offline

OfflineMay 21, 2018

Offline

OfflineI shoot a 445...you’ll do well with cast bullets as long as they are sized correctly. You’ll need to slug the bore, and an egg sinker or a 50 cal round lead ball is perfect for doing it. Basically, you just use a brass hammer (not steel) to drive the ball into the bore, and then use a 3/8’s inch oak dowel to drive it on through. Measure the resulting slug at several points to establish the largest number, then add .0001-.00015 and there’s the diameter you need. Most likely you are looking for a .358 or .359.

Your flame cut does not look serious. I put a similar stripe on mine with 296 powder. I vastly prefer AA 1680 and heavier bullets. 296 has a very narrow usable pressure range, and it’s near max or at max, no downloading with that powder. Although I do load some top end screamers, most of my loading for the SM is around 1400-1450 fps. Easy shooting and easy on the gun, still way hotter than a standard 44 mag. 1680 works well either way, and the tech guy Don loves talking load data on the phone if you have questions. Good luck and let us know how you do!

Blessed is he, whom when confronted with death, thinks only of his front sight...

Dans Club

January 17, 2015

Offline

OfflineAfter squeezing out almost 700 rounds of .357 MAG on the weekend, it got me thinking to get back to getting the proper components for my Super. My reloading supplier (who used to be my neighbour), had actually brought in some 180g gas checked bullets after our discussion that he had been holding onto for me. So, I now have the brass, primers, powder and bullets to get working on a load for the SuperMag. It may take a few weeks to get it done and then testing will commence - I'm intrigued how these will shoot.

Bullets: https://www.grizzlycartridge.com/shop/cast-performance-bullets/38-180gr-wfngc-358-dia-100-count/

Brass comparison: Left to right, .38, .357 MAG, .357 MAX, 180g bullet, compared to a quarter.

[Image Can Not Be Found]

Supporter

Moderators

Dans Club

February 22, 2009

Offline

Offline

Dans Club

January 17, 2015

Offline

OfflineNo lube in the grooves that I can see. I'm listening....what do you recommend, please?

Okay, I have now been spending the evening reading about lubing cast bullets. Looks like I have more work to do. **grumbles**

Edit - okay, after reading way too much than I wanted about lubing cast bullets, I went back to the manufacturer's website and read their "About Us" page:

About our bullets:

- OUR NEW, PROPRIETARY CLEAR LUBE NOW COATS ALL OUR BULLETS.

- Our hunting bullets are cast from LBT style molds.

- Our bullets are cast from virgin alloy and heat-treated to a Brinnel hardness of 18-21. This provides for a hard yet ductile bullet, which will not fragment, or blow-up on the toughest hide or even bone.

- We manufacture both gas checked and plain base for most popular handgun hunting calibers.

1 Guest(s)

Register

Register Log In

Log In Home

Home