April 22, 2019

Offline

OfflineHello,

My first question on the DWF, what is the acceptable value of clearance from the front to the rear, of the cylinder un the frame ?

I have about 1,2 mm and i think it is a lot.

It causes problems of revolving when pulling the hammer. I have to help the cylinder to rotate with the other hand...

I am thinking about machining a tailor made washer to keep the cylinder back in the frame.

What do you think about it ?

August 8, 2016

Offline

OfflineAre you talking about endshake? If so, you could try these shims. I had to buy these for my 715 as there was a lot of front to rear movement which caused light strikes on the primers.

I think you are saying that the cylinder is not turning without help. That would not be endshake. I suspect the barrel cylinder gap is too small. Do you have a barrel tool? If not, get one. If you do, then reset the gap. If you are forcing in the . 006 shim you are pushing the dedent ball in and the gap will be too small. When the gun is used, the cylinder expands and can rub on the forcing cone. It should be set at . 006 on the proudest chamber. The proudest chamber is the one with the smallest gap. Measure every chamber before you tighten the nut. When you measure the shim should slip it in easily. You will learn to do it by eyeball, holding the gun up to a light. It can be set at .003 but always take the tool with you when shooting so you can adjust it. If you use a smaller gap than .006, wipe the face of the cylinder with a rag every couple of loads. A smaller gap gives faster bullets and less chance of blowback.

October 17, 2017

Offline

OfflineSo many possibilities with the information given. A good clear photo would be a great help! We can only guess exactly where the 1,2 mm clearance you are referring to is. 2 mm (about .079 in.) would be an intolerable amount of end shake. Perhaps the cylinder bushing is missing altogether (an early 15-2 bushing can actually fall out with the cylinder removed from the crane), so the face of the cylinder could actually be riding on the forcing cone rather than on the frame (or yoke)

when the hammer is drawn back. Or, if you're meaning 1/2 mm ( about .020 in.), still an incredible amount of end shake, it could mean you have an extremely battered frame that should probably be discarded.

when the hammer is drawn back. Or, if you're meaning 1/2 mm ( about .020 in.), still an incredible amount of end shake, it could mean you have an extremely battered frame that should probably be discarded.

Here is a photo of my early model 15-2 cylinder showing the bushing in place, then removed. Does this look like your revolver?

April 22, 2019

Offline

OfflineHello, thanks a lot for your help.

I don't understant clearly what you mean but i think i must be more precise in my explanations.

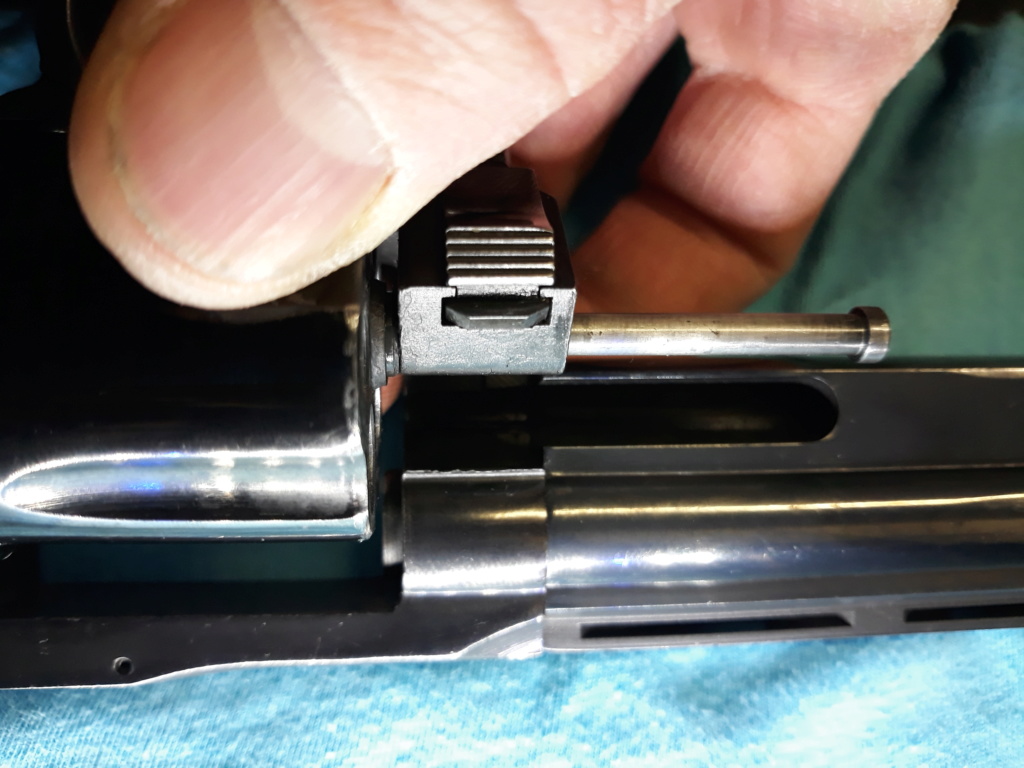

First i have the .006 gage and think i use it properly. When setting the position of the barrel, i make it with the cylinder in contact with the rear of the frame :

But the cylinder, when it is out of the frame, can go further to the front of 1.2mm (0.05 inches).

Here you can see it pushed forward :

And here backward :

So it touches the forcing cone when not hand maintained back in the frame.

Below a photo of the cylinder, i think at least one shim is missing, no ?

May i order one of the shim kits mentioned above ?I must place a lot of them to keep the cylinder 0.05 inches back, no ?

October 17, 2017

Offline

OfflineThe photos and further explanation have helped very much! Thank you for sharing. There is nothing wrong with your DW, and no additional parts will be needed to fix the problem.

Your first statement and photo really explains what is happening. When you set the barrel/cylinder gap with the .006 gage you must NOT press the cylinder back against the frame. The spring loaded alignment ball at the back of the frame holds the cylinder in the forward position gently against the frame when the cylinder is closed, and that is when you set the barrel/cylinder gap at .006

When the gun is fired the cylinder will recoil backward against the spring pressure of the alignment ball, and then come back to its normal position against the frame. This is a unique feature of Dan Wesson revolvers.

What has been happening is this: as soon as you've taken the .006 shim out (I imagine is is very tight because the spring is pressing everything forward) the cylinder is pressed tight against the forcing cone, and the cylinder bushing is not even touching the frame. This is why the cylinder has to be pulled backward to even turn it when thumbing the hammer back. Once you set the barrel/cylinder gap correctly (the shim should only be slightly tight, and DO NOT press the cylinder rearward) you should have no more problems firing the revolver.

Hope this helps.

April 22, 2019

Offline

OfflineThank you guys for your help.

It is perfect now...

I'm very happy to see that i bought a revolver which is not too tired !

Next question about a spring whose i don't know the name and about i wish if it has the correct camber. Should i post it here or open a new post ?

Kindly

Mat

1 Guest(s)

Register

Register Log In

Log In Home

Home