Dans Club

August 13, 2022

Offline

Offlinetrying to change out the blue cylinder in my Nitex gun

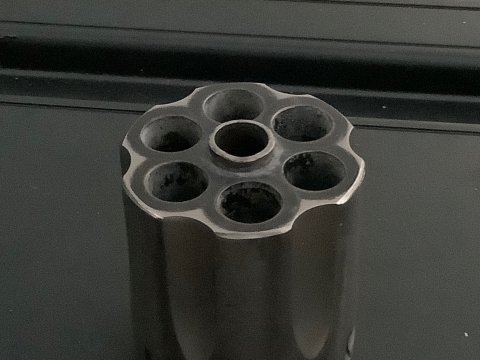

the nitex cylinder will not lock in, appears busing in the center is a bit to far out…attached pic shows this pretty well

in the pic you can see the bushing is about twice as far extended than the blue cylinder

tried to adjust with screw driver but it will not turn…did not want to apply to much force on the screw head

hopefully someone can guide me thru getting the bushing adjusted

thanks

Jack

Jack, the bushing is not screwed in. It is placed over the ejector rod and held in place by a roll pin that fits partly in the bushing but mostly in the cylinder. It is to keep the bushing from turning. If you took a rubber or plastic mallet, or a piece of wood and smacked it hard it will push it back into place. Let me know how it works.

The nitex cylinder can be burnished by putting a brass cleaning brush, perhaps 40 Cal if you have in a drill and smoothing out the inside of plating, or more likely there is a ring of residue inside the chambers from shooting the shorter 38 Special cartridge. If you shoot 38 Special you should follow up with 357 to push out the residue left from the shorter cases.

Dans Club

December 5, 2008

Offline

Offline

Dans Club

December 5, 2008

Offline

OfflineI hesitate to disagree with Ron, but I don't think it is a good idea to try to drive the bushing in further. If it is jammed in position due to the finish causing lack of clearance between the bushing and inside of cylinder, then you will likely end up peening the end of the bushing so that it will no longer fit on the crane. If you cannot remove the bushing then you will likely have to file the end of it down enough to provide the clearance needed to lock the cylinder and crane into the frame. If you get it out then you can measure the depth that it "should" seat into the cylinder and determine if the bushing was seated all the way in. If it was not all the way in, then you will have to find a way to clean excess finish off the inside of the cylinder and the outside of the bushing (if any is on the bushing).

If you have to file the bushing, go slowly and check the clearance often so that you don't remove too much metal from the bushing.

Soak the bushing in your choice of penetrating oil at least 24 hours then use alternating heat and cold to loosen it.

Good luck and let us know how it works out.

You could always send it to DW or a good gunsmith as a last resort.

Dans Club

August 13, 2022

Offline

OfflineStarted with file…that’s not going to happen, really hard steel

now patiently cut the bushing down on the bench grinder, ended up almost flush with the cylinder before installing properly

took the oversized bronze brush on a drill worked all the chambers

will shoot over the weekend…will report back

thanks snake-eye & ole dog

Jack

I was confused again. I thought the bushing on the other end of the cylinder was protruding. That is the one next to the extractor star. So, grinding down the other end, that fits on the crane, is the way to go. Snake-eye is a very good Dansmith.

Nitex or hard chrome, ceracote or other, it is not a good idea to plate a Dan.

1 Guest(s)

Register

Register Log In

Log In Home

Home