July 14, 2015

Offline

OfflineHello all,

I like many of you am a Disciple of the Dan and his fantastic revolvers, but as most of them are used finding one in perfect condition is rather difficult and expensive. With this in mind I stumbled upon a very cheap 15-2 (~$350) that had a good amount of its factory blueing damaged or worn off. After doing a bit of research for cold and hot blueing solutions I found a product called Insta-Blak 333 from the EPI company. On their site it stated that the 333 product line could be used on firearms as a rust preventing cold blue finish. Once I read the instructions I decided to give it a try and ordered their trial kit which comes with everything you need. Below is the link and instructions as well as my trials in using this product.

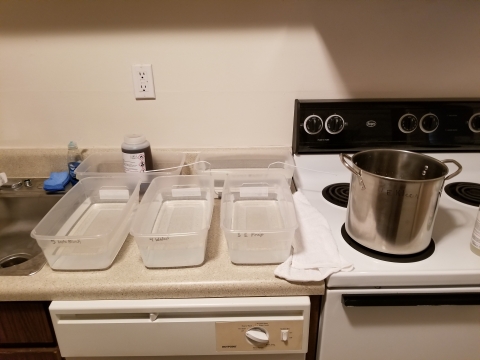

To start off you will need several containers (about 6), A heat source of some kind (I used a $9 hot plate from Wal mart), a pot, and some way of suspending parts in the solutions (a metal coat hanger works perfect).

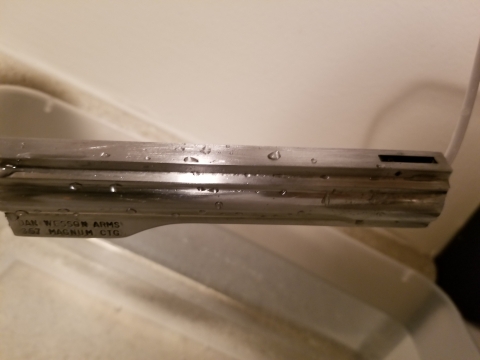

Now the most important thing about any form of refinishing is good metal preparation. However this is much less involved than you would believe. As seen below I removed all the factory blueing that was left on the shroud with 1000 grit sand paper and 0000 steel wool.

Once the metal is mostly clean we move to the actual blueing process.

Step 1

Dunk the piece you are trying to blue into the acid bath that comes with your trial kit called E-Kleen 148-E. The acid eats off all the oil and impurities on the metal that could interfere with even finishing. The acid should be kept between 120-150°F. and is the only component that requires heat to operate properly. Leave the metal in the bath for at least 5 minutes and up to 10 minutes. Once the acid has had time to work, move the metal out of the acid bath and into the first rinse of water.

Step 2

Rinse the metal in a bath or running water for 1-2 minutes. I like using a ice tray tub filled with water and will agitate the metal through the water a few times every 20-30 seconds to ensure all the acid is removed.

Step 3

Place the metal in the prep solution E-Prep 258. Leave in the solution for 2 minutes and agitate just as you would in the rinse bath. You may see the metal start to oxidize/rust but do not be alarmed.

Step 4

Rinse in water as previously described in step 2.

Step 5

This is were the magic happens! place the metal in the blueing agent called Insta-Blak 333 for 2-5 minutes and watch the metal turn a deep shade of black.

Step 6

Rinse in water as previously described in step 2.

Step 7

Seal the finished metal in the oil that comes with the kit called E-Tec 503 and agitate for 1-2 minutes, then let the metal air dry.

Notes

-Above is a paraphrase of the instructions that EPI has listed on their website, however in my trials I found that the parts developed a smoother black finish with a longer soak time. I soaked mine in the oil several times in the 24 hour cure time and got a less dry and matte finish.

-I also wouldn't recommend completely stripping the old finish off the old part like I did with the barrel shroud. You can't really see it on camera but my shroud came out very patchy and uneven the first run through but after a second run through the bath it came out a even deep black like the rest of the gun that had the original blueing still on did.

-This process is a good substitute for a hot blue finish and certainly easier, faster, and less involved than other cold blues I've seen videos of but it is not really as good as a true hot blue finish. I suggest trying it on some old tools laying around first before commiting to doing this to your firearms.

Disclaimer: I'm not a professional and just an average joe, your experience with this product may be different than mine.

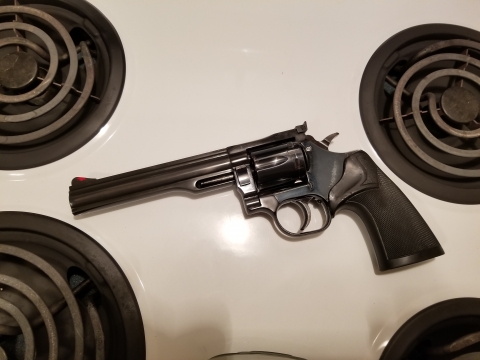

My 15-2 completed

some screwdriver bits that went through the process with my dan.

I'll put a picture up some time in the near future of my revolver after the second time I blued it as it did not take as even as i like the first time.

What do you guys think?

Dans Club

January 17, 2015

Offline

OfflineGreat write-up. More detailed pics would be nice to see how the bluing turned out. I have redone a few parts and shotguns over the years with various bluing products, none of them particularily impressing me with the gloss of teh old days.

For stripping off old bluing, you can soak your items in white vinegar - it strips rust right off metal

1 Guest(s)

Register

Register Log In

Log In Home

Home