DWF Supporters

March 5, 2024

Offline

OfflineOK As some of you know I have a bunch of DW parts available for sale here on DWF... and that includes several large frame SS cylinders. (moved to gunsmithing rwsem)

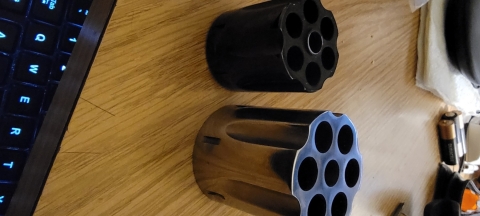

Now I am not a gunsmith nor a DW expert.... so, after a member bought one of my .357 SM/Max cylinders he went to mount it in his frame.. but there appears to be an issue, see photos:

As you can see, my cylinder do NOT have the small raised lip on the front. All 6 of the cylinders do NOT have said lip.

Raises a bunch of questions:

1. Are these really DW cylinders??

2. If yes, where's the lip?? (I check my own .357 SM/Max in SS, and the lip appears to be there)

3. Were there early/late design changes I don't know about where the lip was added/removed??

4. Is/was this omission by design for replacement cylinders with purpose to allow a "ring" of the right size to slid on to the crane to get the spacing just right for a particular frame?

What say you all???

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

OfflineSupporter

Moderators

January 24, 2009

Offline

OfflineSCORPIO said

Looks like those are bare cylinders with no busings installed. It looks correct, just going to need a bushing to make it work.

Exactly, install (or have DW install) a bushing, and it should work fine.

*EDIT* Disregard my initial post, I was recalling a bushing at the front of the large frame cylinders. It's been a while since I've had one out &in hand! Woops, my bad! Read the later posts here to find the real truth to these cylinders...

DWF Supporters

March 5, 2024

Offline

OfflineSo that lip is the end of a bushing?? The center hole in the cylinder is not the same size as the crane rod??

Busing as in like this?? (guessing I would need a SS edition for the SS cylinder)

Dan Wesson Ejector Rod Bushing New Factory OEM

On a .357 mag cylinder it looks like this (ejector end)

I can clearly see it... on the SM, not so much:

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineThe ejector rod bushing sets on the ejector spring- that ebite part is not what you would need.

Edit// I have two SM cylinders out right now and cannot see that it's a separate piece. There was an engineering change that ended up cutting the gas ring onto the face of the cylinder, so the part you need is a cylinder gas ring for the older style cylinder. I'll add that there were several engineering changes to ejector stems over the years, to complicate things.//

Technically, the glass is always full; half liquid, half air....

Dans Club

February 24, 2013

Offline

Offline

DWF Supporters

March 5, 2024

Offline

OfflineThanks Ole Dog... The small frame is different (literally smaller) from the large frame from what I can tell.

I checked with Numrich Gun Parts and Jack First Inc. and found some on both sites... As I need SS version, Jack First Inc. had those for a .44 so I ordered 3 (have 6 cylinders that would need those but figured I test the first... $20 each). Numrich had the blue edition.

Now for a question of semantics... bushing vs gas ring

Based on what I'm seeing, they are the same.. (LOL) or different. On those parts websites they have a bushing that has that lip and some non-lipped versions they call a gas ring... but no details on the which versions of the DWs (other than large or small frame) the part is intended for.

I also found this YouTube video which was helpful regarding what he calls a gas ring but with a lip...

Anyway, still having fun figuring this out...

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineI didn't see any 44 Gas Rings on Jack First, only 357. The ejector rod bushing is not what you need- I'd cancel the order if it was for an ejector rod bushing.

The ejector rod bushing is on the ejector rod, the gas ring is the center of the cylinder. Here's a 740 I have torn down currently, to show the two together:

Technically, the glass is always full; half liquid, half air....

DWF Supporters

March 5, 2024

Offline

Offlinerwsem said

I didn't see any 44 Gas Rings on Jack First, only 357. The ejector rod bushing is not what you need- I'd cancel the order if it was for an ejector rod bushing.The ejector rod bushing is on the ejector rod, the gas ring is the center of the cylinder. Here's a 740 I have torn down currently, to show the two together:

The gas ring... is it a pressed in piece or machined "in"???

On Jack First they have ejector rod busing, which given it had a lip, and the gas ring they have for a .357 does not, lead to the confusion of the terminology.

Here is the gas ring they have:

Unless you just don't install all the way in so it sticks out that 1/8" (??).

Sorry this is turning into a Gunsmithing 101 thread... but there is no parts reference to a gas ring in any DW documentation I can find and only have photos like yours with the gas ring already installed... none of the naked part.

October 18, 2017

Offline

OfflineThe gas ring was used on the earliest DW’s. They machined a “pocket” into the cylinder face then inserted the gas ring which was seated to the proper depth to allow the correct headspace. All “pork chops” were made this way as well as the early 15-2’s. I was unaware that this method was ever used on a large frame DW. Anyway, here’s a photo of one of my early .357’s showing how it works. You need the correct part, a good machinist and a lot of patience. Good luck!

Supporter

Moderators

Dans Club

February 22, 2009

Offline

Offline

Dans Club

October 26, 2008

Offline

OfflineAs 3ric stated if these were going to be some experimental attempt at using the interchangeable “bushing” there would need to be a pocket machined into the cylinder for said “bushing”. As there isn’t machining would need to be done to the cylinder and a custom bushing made. The small frame bushing won’t work, large frame crane measures approximately 3/8 (.375) and small frame measures 5/16 (.312). From a manufacturing standpoint it would make no sense for them to machine the counterbore for the bushing as a separate operation since you were already there to do the bore for the crane and all they’d accomplishing by doing it separately would be to introduce error into matching the existing bore (runout, out of parallel/perpendicularity etc.) Also, if you guys were to be able to examine them in person you’d see the obvious finish of a belt sander then a very quick hit on a buffer. It is not a machined (turned, milled or surface grinder) surface which I am having trouble getting a picture of.

In the following pictures I have one of the cylinders in question (41 in this case) an early Monson 44 (before they started doing the letter prefix), a 44S prefix era Monson and I grabbed a picture of a Norwich era cylinder (360 DW) The big obvious thing to look at is the radius where the collar meets the face of the cylinder. They all are one piece no insert.

I do have one last thing RichardsDWs has handled this very professionally thus far even offered to pay return shipping which I will likely be sending these back to him. He genuinely seemed to not know the issue with the cylinders and I would have no problem doing business with him in the future assuming he does send the refund once I box them up and get them in the mail.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineNo issues with my order as well and would do business again.

I still think a machinist could counterbore and fabricate a bushing but that would induce more cost. Cost could be economized by doing several at one time, but still a hassle. As is, maybe the best thing to do is make them into pen holders on a piece of nice walnut and sell on ebite?

Technically, the glass is always full; half liquid, half air....

1 Guest(s)

Register

Register Log In

Log In Home

Home