October 16, 2014

Offline

OfflineAdd me to the list of people able to use their DW again and with confidence. Thanks to Shootist 357 in particular but to others as well on this thread. These are wonderful guns and I am hoping that they thrive being part of CZ. I will begin looking for one of their stainless small frame 357s model 715 I think. Meanwhile is good to keep the old ones going and the forum and places like EWK arms and Numeich are invaluable parts from the later and knowledge from the former.

I am am going to get a couple parts from CZ, the connector and a new hand etc., but those are for down the road and insurance mostly. Oh yeah probably a 2.5 barrel and maybe an 8 inch.

Now I relly am one of those people with little. Mechanical aptitude and a paucity of spatial reasoning so if I can do it anyone else can, no really.

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

OfflineFebruary 15, 2015

Offline

OfflineGreat tutorial. I just went through all this with my 15-2 including the new springs though I probably didn't polish nearly as well for laziness. I will say mine appeared to be finished much better from the factory that the gun used for the example pictures.

SA pull came out at ~3.5 lbs. DA was still well off the scale (>8lbs) of my cheap Wheeler gauge.

I learned a bic pen with the ink cartridge removed makes a perfect hammer spring removal tool. Also, it is a good idea to check the trigger overtravel screw while the gun is apart. Mine needed almost 2 turns out.

I really love the engineering that went into these guns. They come apart and go together so easily and logically. I really love the use of hex heads for all the screws. Flathead screwdrivers and polished blued surfaces always make me nervous

Supporter

Range Officer

Dans Club

Range Officers

Members

July 2, 2011

Offline

Offlinewrxguyusa said

Great tutorial. I just went through all this with my 15-2 including the new springs though I probably didn't polish nearly as well for laziness. I will say mine appeared to be finished much better from the factory that the gun used for the example pictures.SA pull came out at ~3.5 lbs. DA was still well off the scale (>8lbs) of my cheap Wheeler gauge.

I learned a bic pen with the ink cartridge removed makes a perfect hammer spring removal tool. Also, it is a good idea to check the trigger overtravel screw while the gun is apart. Mine needed almost 2 turns out.

I really love the engineering that went into these guns. They come apart and go together so easily and logically. I really love the use of hex heads for all the screws. Flathead screwdrivers and polished blued surfaces always make me nervous

Congrats. You are now an Official Average Joe Expert. Now go give that bad boy a work out and give a range report!

To the paranoid people who check behind shower curtains for murderers:

if you find one...what's your plan?

Supporter

Moderators

January 24, 2009

Offline

Offlinewrxguyusa

I really love the engineering that went into these guns. They come apart and go together so easily and logically. I really love the use of hex heads for all the screws. Flathead screwdrivers and polished blued surfaces always make me nervous

And that right there is much of the genius of the DW design, good to know there's still people who "get it"!

In a perfect world Dans would have the DA of a Python. Wolff springs help smooth out the scratchy feeling

Use the 8 lb. Spring. The short hammer throw in both DA and SA help the accuracy. If you push a brush down the barrel both ways you can tell the barrels are "choked" like a Python. Another reason for the accuracy.

August 17, 2015

Offline

OfflineHad some misfire issues with my 15-2. Used all the advice from the Forum. Backed off the grip screw, tightened the cylinder ball, replaced the springs,etc . Although the process took a few trips to the range to eliminate all possible issues, finally all misfire issues have been resolved. Thanks to all who contributed.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineOctober 28, 2014

Offline

OfflineThanks Guys for this post. I was recently having issues with my trigger return and using the average joe tune up I was able to successfully disassemble and reassemble my 15-2 along with ordering a set of springs from Wolf Springs. My 15-2 is repaired and shoots as good as new.

Morris

December 19, 2015

Offline

OfflineI tried the average joe tuneup with my "never fired" Palmer 715. It went very well.

I've been inside before. Disassembly 5 minutes

I stoned all the stated areas with (3) progressively finer stones. 1 hour

I polished all the stated areas with a 1600 grit polish cloth. 1 hour

Reassembled. 5 minutes.

My Palmer 715 went from 13 lb pull in DA to 12 lb pull.

It went from 5 lb pull in SA to 4.3 lb pull. These numbers and the feel are unacceptable.

I can not notice any smoother trigger. The inside was new and clean. Dry firing did not help.

I will try the EWK springs next and perhaps the Wolf as well.

With all the great reports I have read here, I have to say I was disappointed both in the Palmer 715 and in the action job. This is not my first picnic. I have a safe full of S&W and Colt revolvers that have not had these trigger issues. Their DA triggers don't stack like this, don't grind like this, and don't have 3 hiccups on the way back. Are these, unfair comparisons. This 715 is like new. It's been in a vault for 3 decades.

I know I will lighten the pull with new springs, but I don't expect the feel to change much. I did the average joe action job without new springs to find out how much it would change with just the action job. The answer was - not much on this gun with my action job.

I have 5 like new Monson DW 357 SuperMags and their triggers are just as heavy (11, 4) but their actions are very smooth without any action job. I now question whether my expectations were set by the large frame SuperMags; and mostly in SA. I shoot SuperMags for distance and I don't shoot distance with DA. I got hooked on DW shooting SuperMags. This is my first Palmer gun and small frame. I bought the Palmer 715 to shoot my 25 yards course in DA.

I now question whether the small frame DW triggers just do not match the build quality of the SuperMags. I don't know if they are even the same trigger mechanism. This is my first Palmer build?

Any comments would be greatly appreciated.

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

OfflineThe Monson and Palmer internals are identical so that should not have any bearing on the issue. The large and supermag frame guns have totally different internals to the small frame guns so a direct comparison is not really possible. I have some large frame guns that are a bit quirky in DA and some small frame guns that are butter smooth in DA. I think maybe you need to go back inside and go over things again. If the gun is really unfired and 30+ years old, I would suggest soaking the internals and perhaps the frame in something like automatic transmission fluid overnight to allow the metal to 'absorb' the lube, the reassemble and see what you have. The springs will lighten the pull but the polish and lube should help the DA.

Anything worth doing is worth doing well.

My father

If a man designed it, and a man built it, then a man can fix it.

My grandfather

December 19, 2015

Offline

Offline

Scorpio,

Scorpio,

thanks much for the info. You helped eliminate a couple of options. Monson vs Palmer.

and Yes. I am headed back in to look for more wear spots as soon as the new springs show in the mail. That's an interesting idea about soaking in lube.

Your comments about some good SA and DA pulls on both frames also puts some real shade on the idea that it is a frame size issue.

I will also try that ease up tension on the hammer spring test.

I don't give up easy, but I can get frustrated pretty quick.

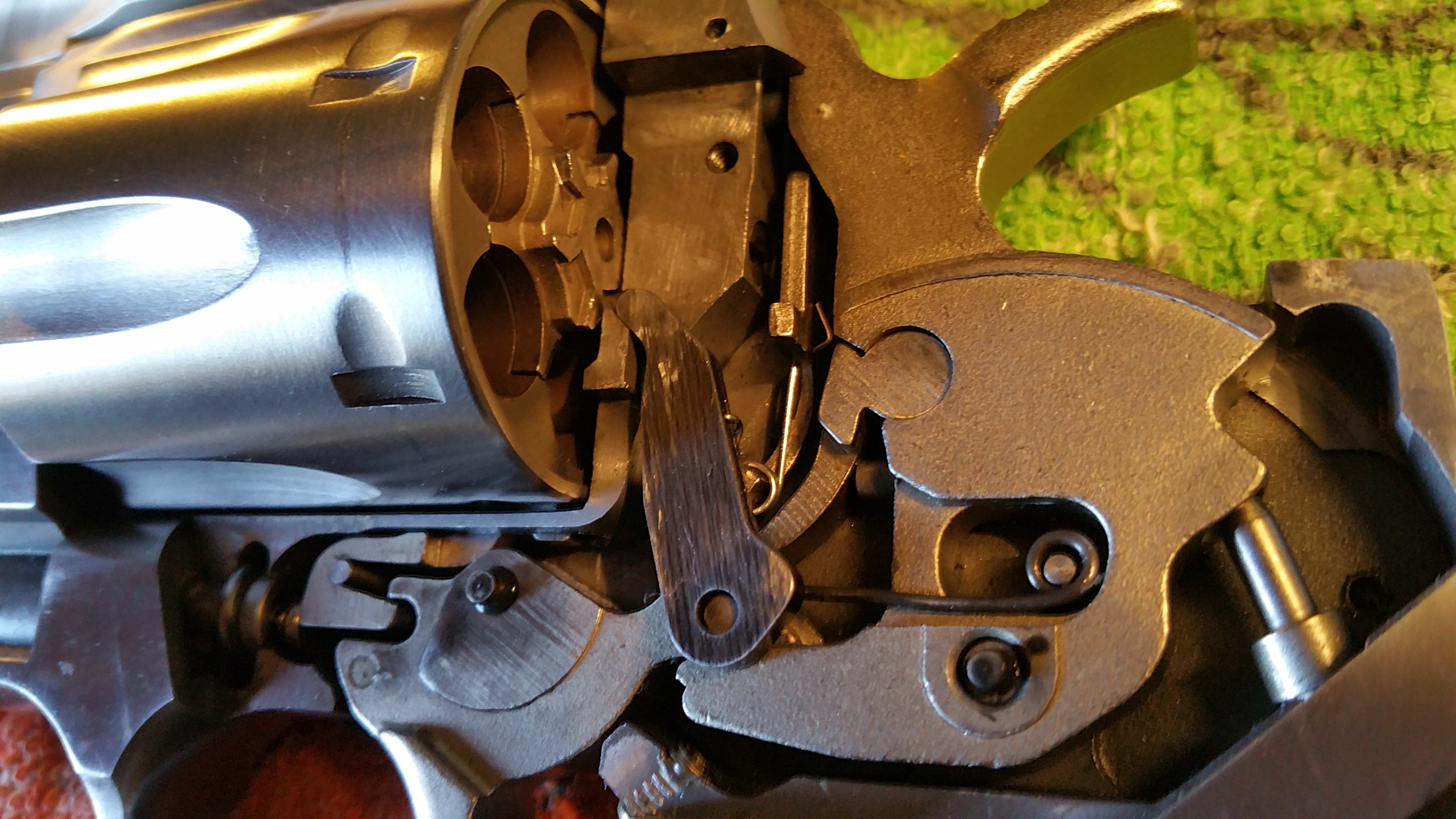

Here is a few picks of what it looked like inside before I started:

December 19, 2015

Offline

OfflineOK, guys,

My DA pull is 12 and my SA is 4.3 lbs.

I tried loosening the hammer spring tension by backing out the grip screw. The screw goes in about 4 full turns. I backed it out until it only had one turn on the threads of the grip screw. I measured the DA at 11+ and the SA at 4+. So yes, I can reduce pull weight, but not much.

I assume that this test is similar to putting in a lighter hammer spring?

Prescut

DWF Supporters

Dans Club

Moderators

November 17, 2008

Offline

OfflineI am no expert but I doubt the grip screw has any effect on trigger pull weight. I suspect your revolver just needs a little more tuning than others. Most guys report good results with the AJT but nothing works every time and every company builds a lemon occasionally. I suspect you just need to keep at it until you find the sweet spot. All just my opinion. Good luck and I hope it works out for you.

LB

Wisdom is merely the realization of how little one knows, therefore I am wise.

Dans Club

December 5, 2008

Offline

OfflineYour gun looks virtually unused from the pics. That might be some of the problem, if the parts need to "wear in", although it shouldn't make much difference. Every gun is different, but your problems are not common.

I may be wrong, and I know someone will correct me if I am, but I don't think you can reduce hammer spring tension by backing off on the grip screw. Seems to me the only way to back off hammer spring tension is to back out the spring seat, which is the part that the grip screw actually screws into. Most of my guns have this part fixed in place by the factory, presumably to keep it from vibrating out or moving when you tighten or loosen the grip screw. I have seen guns where it is not fixed in place and that can create problems on its own. If yours is not fixed then you should be able to adjust the tension till it is where you want then Loctite in place.

June 29, 2012

Offline

Offlinelbruce said

I am no expert but I doubt the grip screw has any effect on trigger pull weight. I suspect your revolver just needs a little more tuning than others. Most guys report good results with the AJT but nothing works every time and every company builds a lemon occasionally. I suspect you just need to keep at it until you find the sweet spot. All just my opinion. Good luck and I hope it works out for you.

LB

That's right, the screw has no effect but the nut she is screwing into has an effect. By screwing or unscrewing the nut into the frame you push more or less on the hammer spring and that has an impact on the trigger weight.

February 4, 2016

Offline

OfflineI am trying to do this myself right now and am having a problem with one of the springs I got. The trigger return spring is in place where it should be, but it keeps jumping off of that little ledge where it rests on the trigger and down onto the post that fits into the side plate. When this happens the trigger gets stuck in the fired position and I have to push it forward. Sometimes I can't get the hammer to stay locked back either. This only seems to happen with the new spring and it doesn't matter if the side plate is on or off as I have played with it a lot trying to pin down the problem. Only holding some pressure on the cylinder hand seems to keep it on track. I have reached out to wolff about the spring to see if maybe they think it's misshapen or otherwise defective. If it's not that then the only thing I can think of is the ledge where the spring rests might be screwed up. Does anyone have any ideas on this?

I left the cylinder hand out of the pictures so it's not in the way.

Sometimes it can be difficult to slide the sideplate on and keep the hand and trigger return spring in position. Once the sideplate is on though it holds the spring on the ledge. Does the little ledge slope down towards the hand. A little bit of honeing can reestablish the ledge and help keep the spring on the ledge. Dry any excess oil off. You mention new springs. Are they Wolff or some other brand. As a last resort, put back the original spring. BTW, photos are not showing on my phone. I may be way off base.

1 Guest(s)

Register

Register Log In

Log In Home

Home