July 10, 2012

Offline

OfflineI got this Model 15-1 as part of a trade and decided to Dykem it and tune for demonstration purposes. Just FYI, do not Dykem your revolver if you like the finish on it, Dykem has something like acetone in it and will eat blue.

First (assuming you have checked to see if it is loaded), remove the barrel and shroud assembly with a barrel nut wrench, the cylinder/crane will fall out be careful not to send the bolt detent spring to Canada (or the USA if you are in Canada).

Take the screw out of the grip and slide it off.

Cock the hammer and remove the rear side plate screw, screw it into the hole the grip screw came out of.

Take the front side plate screw out and rattle/tap/massage the side plate off.

Remove the cylinder hand.

Poke the bolt up into the slot in the frame to clear the trigger, release the tension from the trigger rebound spring and remove the trigger, followed by the transfer bar, and bolt.

Pull the hammer out.

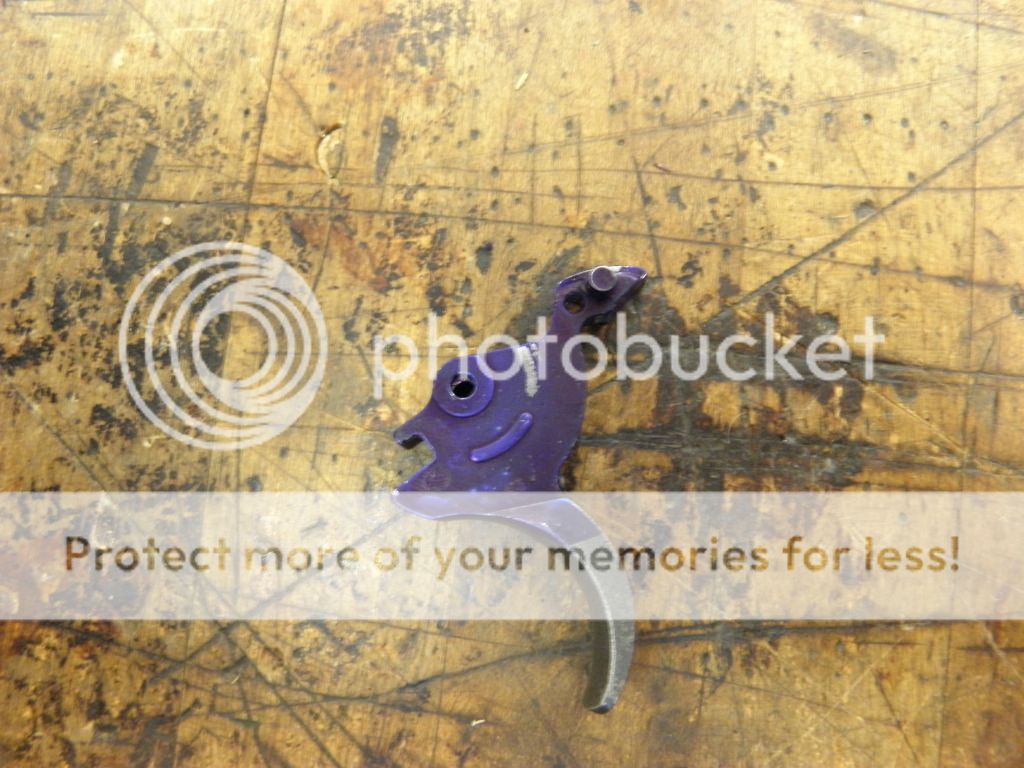

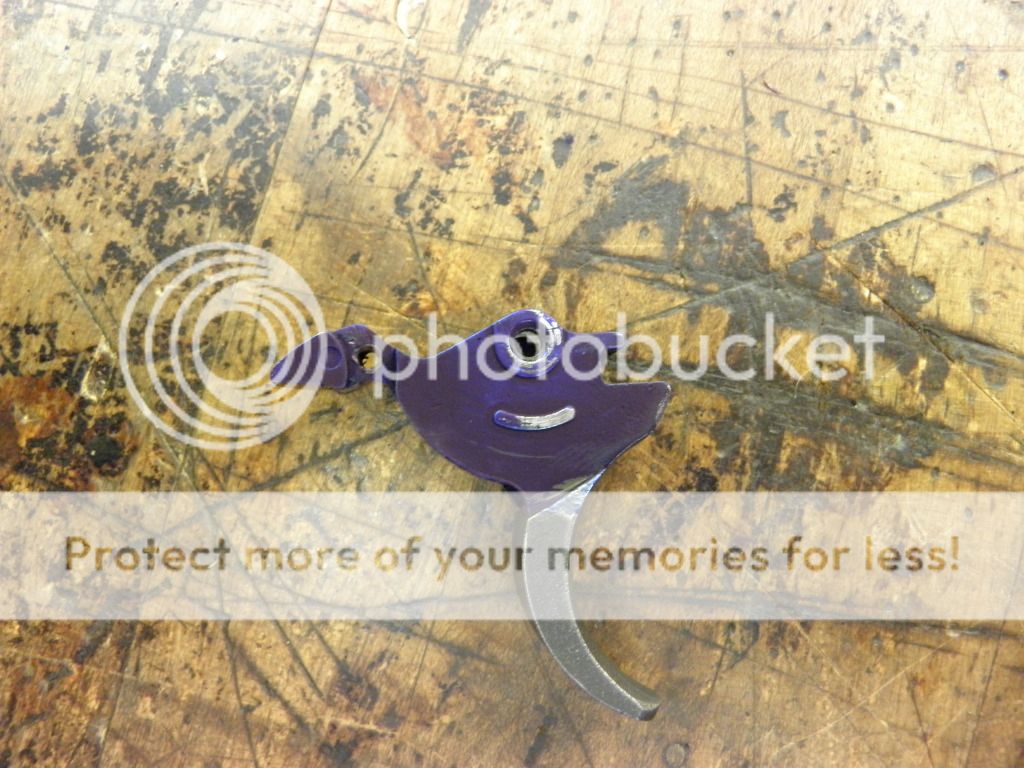

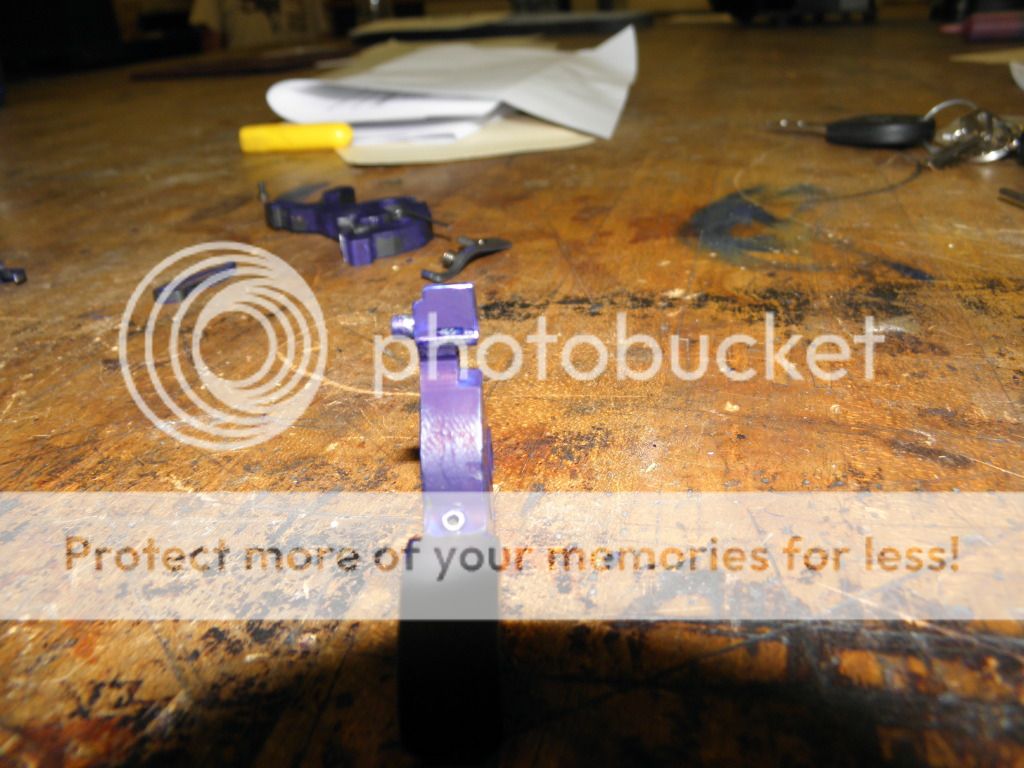

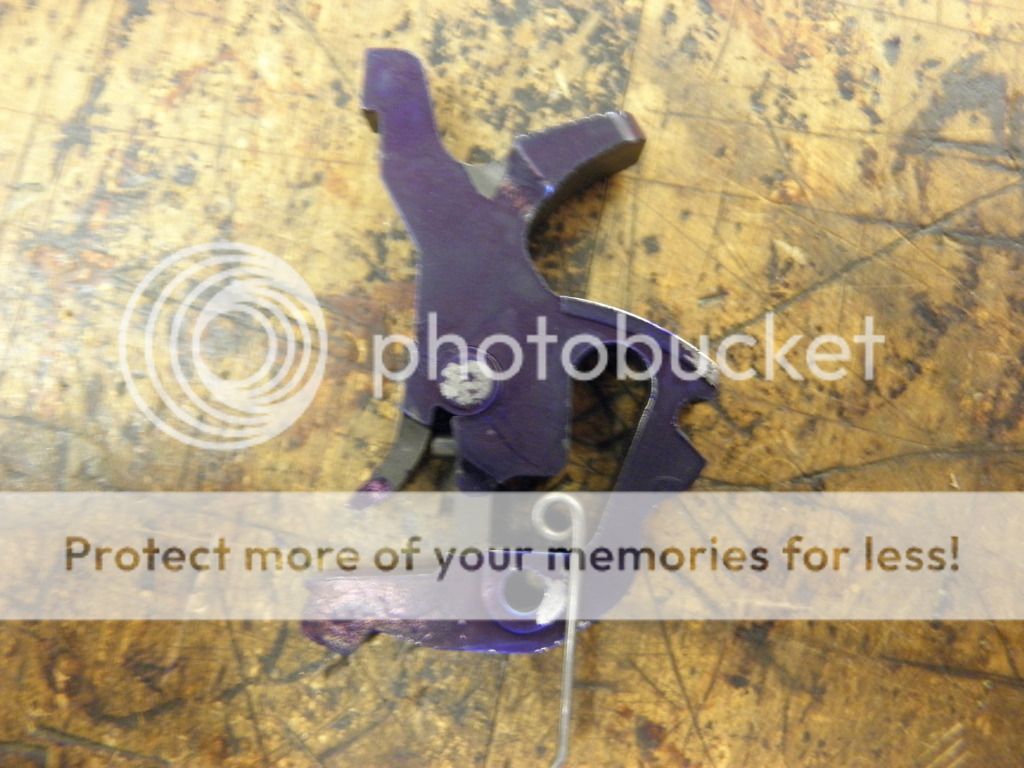

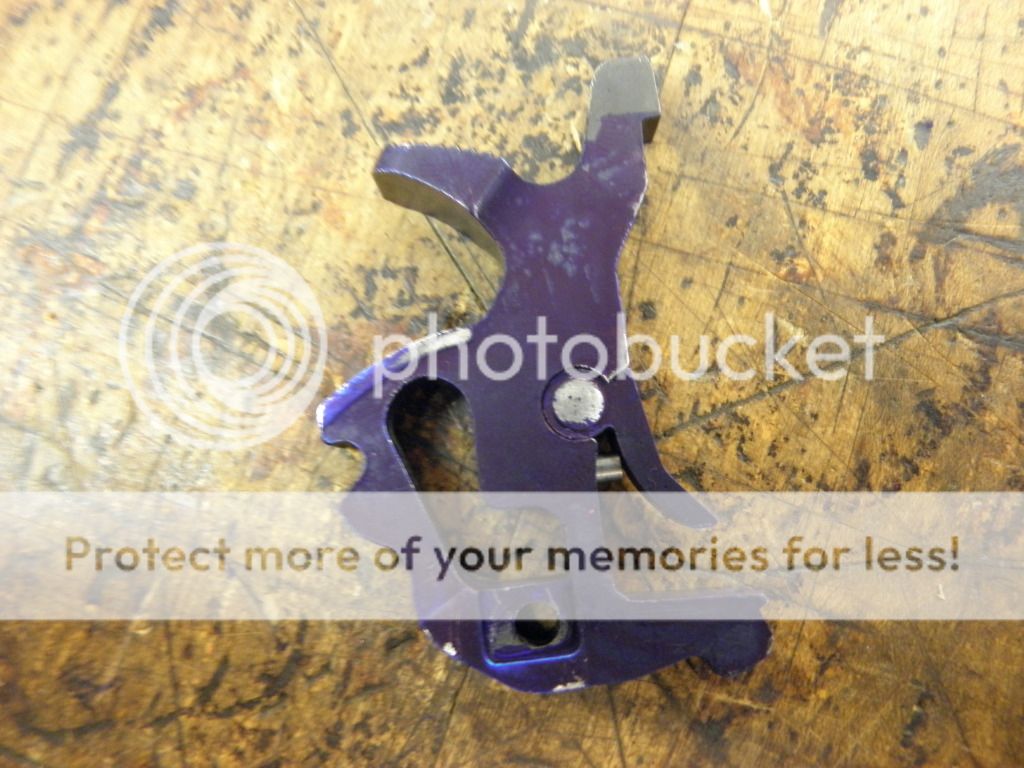

Here is what everything looked like after it was all DyKemed up:

I am always looking for broken, ugly, or cheap guns to buy.

(I know it isn't a DW but, it's a cool pic)

July 10, 2012

Offline

OfflineAfter reassembly and cycling, this is what we have:

Notice one side of the trigger has some heavy wear and a gouge, this was caused by that little nipple that keeps the cylinder from backing out when open. It is pressed into the side plate and mine had a burr sticking off, I took a file to that little...

I am always looking for broken, ugly, or cheap guns to buy.

(I know it isn't a DW but, it's a cool pic)

July 10, 2012

Offline

OfflineAll of the areas that are shiny in my pictures should be polished with a hard Arkansas stone.

Note: Do not touch the mating surfaces of the single action sear, unless you want a DAO or an incredibly unsafe gun.

The rounded top of the trigger should be smoothed and round-it will contact the double action sear (the little flapper on the hammer), the back side of it has a little flat spot, make it round like the rest of it.

The front of the trigger (where the bolt contacts): the top should be round, the bottom of the shelf should just get the burr knocked off (two or three strokes).

Polish the top (flat side) of the double action sear.

Round over the Top of the single action sear (the leg the double action sear is pointing at)

Smooth the round part of the bottom of the hammer.

The double action pull on mine was too stiff and loaded up toward the end so I:

Carefully removed the mainspring (I not-so-carefully removed it once and it stuck a 1/4 into the drywall 10 ft away) (don't tell my instructor).

I cut two coils off and finished the spring by heating a spot on a piece of sheet metal bright red and pushing the unfinised end to it with a pair of pliers.

I reinstalled the mainspring by placing the frame in a vise, pushing the guide rod into its hole with a punch that had a ball of duct tape on the end and had another student put the side plate screw in.

After reversing the disassembly instructions; mine had a smoother action than an out-of-the-box Smith but not as smooth as a well tuned one. My single action breaks between 2.5 and 3lbs.

I am always looking for broken, ugly, or cheap guns to buy.

(I know it isn't a DW but, it's a cool pic)

Supporter

Moderators

January 24, 2009

Offline

Offline1 Guest(s)

Register

Register Log In

Log In Home

Home