Supporter

Range Officer

Range Officers

May 2, 2009

Offline

OfflineOk, I finally pulled one completely apart  … And it is filthy. It was missing the small nut that holds the entire assembly together, so I figured I might as well pass on some knowledge…

… And it is filthy. It was missing the small nut that holds the entire assembly together, so I figured I might as well pass on some knowledge…

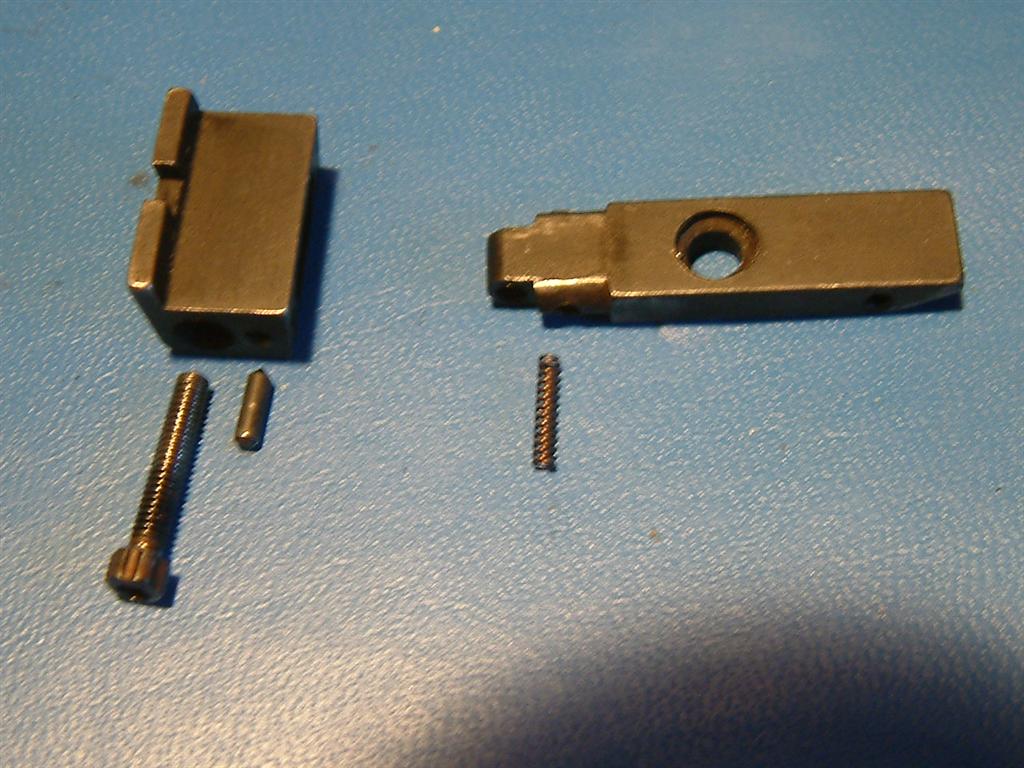

Here's what the sight looks like when you pull it apart–there is a small ball bearing you cannot see in this photo–it will be shown later.

From what I can tell, there are only two reasons your rear sight will get loose. First reason is the small lock-nut on the windage adjustment screw is loose. Unless you are fairly handy at making your own gunsmithing tools, not much you can do about this. It takes a small wrench similar to the barrel nut wrench. If this nut is loose, it will allow a small amount of play in the windage screw.

The other reason it may have some play is the windage screw itself. As you can see in the following photos, the windage screw threads are very fine (maybe 3-56, I'll have to mic them). With threads this small, it doesn't take much wear to make them loose. As you can see in the following pic, the windage screw goes into the hole in the left of the base.

If you do any significant amount of adjusting to your rear sight, you are going to wear this thread out fairly quickly. Any minute amount of rust or grit on these threads and they are pretty much done. This makes it easy to see why a DW with a frozen rear sight takes a lot of work to get loose. Any rust on these threads will require a LOT of soaking. Best bet may be to remove the rear sight completely and toss it in a jar of solvent.

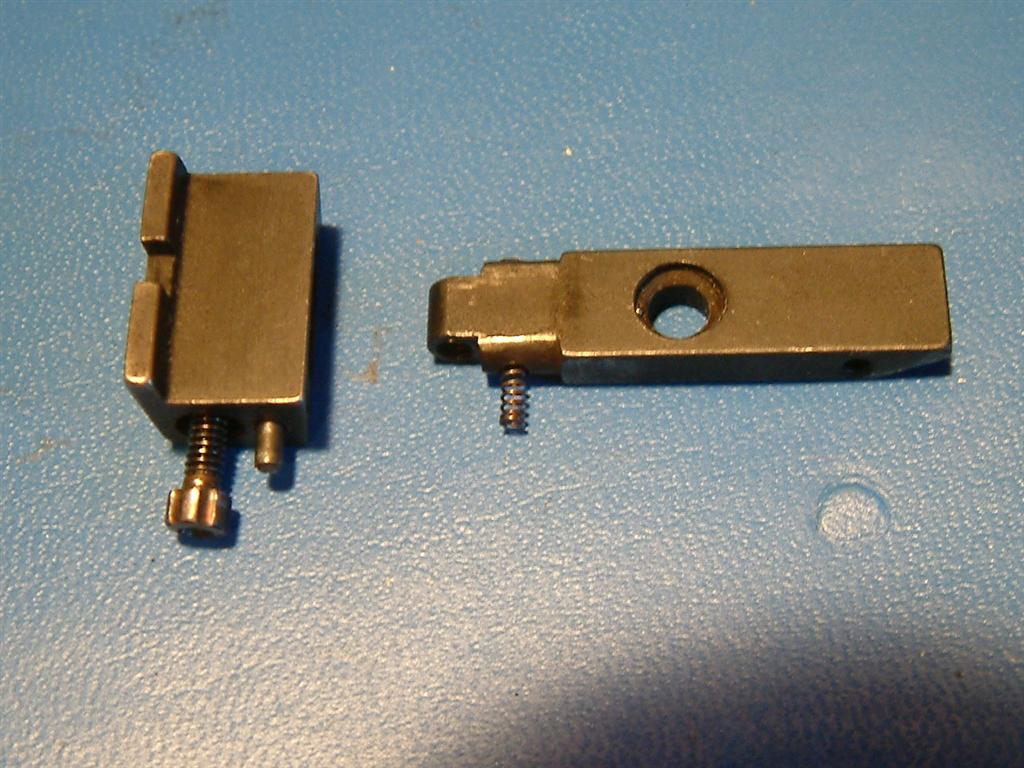

The next two pics just show how everything fits together–refer back to these when we discuss the ball bearing…

A few things to notice in the ABOVE pics… The small knurling on the windage screw head rides on the ball bearing and provides the "clicks". The pin to the right of the windage screw holds the spring in the sight (spring keeps tension on sight for adjustment). This pin is captured by the ball bearing also… Let's get to the ball bearing…

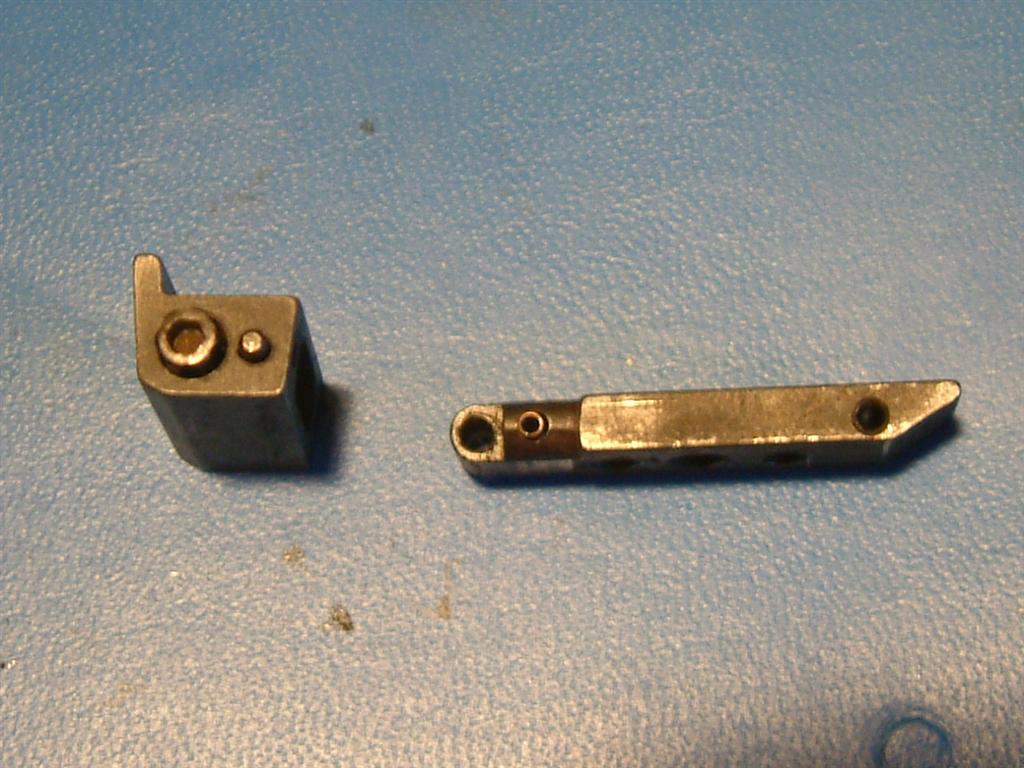

First of all–yes, it is filthy !!! Straight off the gun. The ball bearing is located between the windage screw head and the spring retaining pin. Once the windage screw in placed fully into the sight, it pushes the bearing slightly over the spring retaining pin and keeps it from shooting back out the hole. Here is what it looks like assembled.

As far as tightening up a loose rear sight…. You MAY be able to lightly tap the threaded hole with a hammer to tighten up the threads. You could try replacing the screw if you could find another one. Hopefully DW will be producing sights soon and we won't have to worry about it anymore  .

.

Now, if your rear sight is frozen in place–as you can tell from the pics, there is no good way to get solvent to the frozen area. Best bet is to soak the entire sight.

SHOOT

Supporter

Range Officer

Range Officers

May 2, 2009

Offline

OfflineKnock the cross pin out first with a 1/16" punch or drill shank. There are two springs under the sight–be careful not to lose them.

With the pin in place, you are probably binding the sight a little when trying to remove the screw.

***EDIT -- Just noticed you have the other sight style. removal from frame should go as I explained, but not sure if internals are the same.

SHOOT

Supporter

Moderators

January 24, 2009

Offline

OfflineSupporter

Range Officer

Range Officers

May 2, 2009

Offline

Offline1 Guest(s)

Register

Register Log In

Log In Home

Home

aboard, Jeff.

aboard, Jeff.