DWF Supporters

February 8, 2019

Offline

OfflineUpon closing the cylinder, it does not lock up until the hammer is very slightly pulled back. In other words, it will freewheel in a similar manner as when the hammer is partially retracted except that the catch (not familiar with the correct name of part) is not retracted. When the hammer is ever so slightly retracted, I can see the catch move a small amount and the cylinder locks in place. My model 15-2 does not do this.

1. Is this normal behavior? The 44 has done this as long as I remember.

2. If this is not normal, is this a cleaning issue? I've tried adding a drop of lube from above and below and did not change the behavior.

Thanks!

BS

Edit: I don't know why I called this a 744....I had it logged correctly in my tracking spreadsheet as just a model 44. Dought!

That catchy thing is called the bolt, and it slides into the slots on the cylinder to lock up the cylinder when fired. Freewheeling is not normal. I have taken apart dozens of small frame guns but never a L large frame. In the topic Gunsmithing is a picture tutorial. It is not as easy as the small frame guns but the mechanism of the large frame guns is actually less complicated. It could be a trigger return spring that is broken. Does the trigger return after firing the gun, or dry firing? Folks are busy in the summer but someone will be along that will know exactly what it is.

DWF Supporters

February 8, 2019

Offline

OfflineHi, thanks for the response. Yes, the trigger returns after firing. If I didn't know this wasn't normal, I'd say the gun has always functioned flawlessly.

I've owned the gun since new, in about 1986, and as far as I can remember, it's always functioned this way. Even though I've worked on a variety of firearms, I've never taken a revolver apart....have always shied away from it. I watched a pretty good video on disassembling the large frame DW and didn't seem all that difficult. I may give it a shot.

I'm still interested in thoughts on what may be causing this.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

Offline

Dans Club

February 24, 2013

Offline

Offline

DWF Supporters

February 8, 2019

Offline

OfflineI've partially disassembled the gun. I am unable to remove the cylinder and suspect the barrel has to be removed to do so? Note that the U shaped clip has been removed.

Will someone please confirm.

I've also been unable to break the barrel nut loose. I'm afraid I'm going to break the spanner tool. What is the recommended method to get this nut loose when very tight?

Here's what I've seen so far:

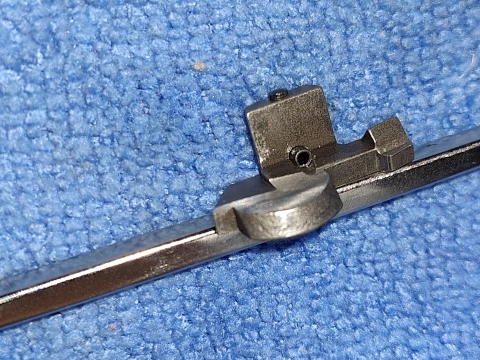

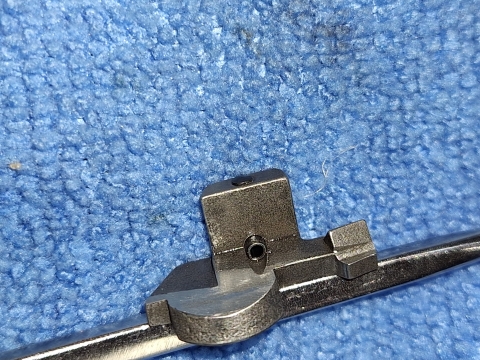

It's very clean inside. The spring and plunger that inserts into the cylinder support shaft are clean and move freely. There is a tiny spring/plunger that inserts into Bolt, from the side. There is a tiny roll pin that would appear to hold both the spring and plunger in place....in other words, it appears to assemble from the pinned end and held captive. The spring behind this tiny plunger does not push the plunger fully proud of the side of the Bolt. I can tap the bolt and get the plunger to extend slightly...maybe .015", but that's as far as it will move out. I would think the spring behind it would be designed to push that plunger to the end of its travel. Will someone please confirm?

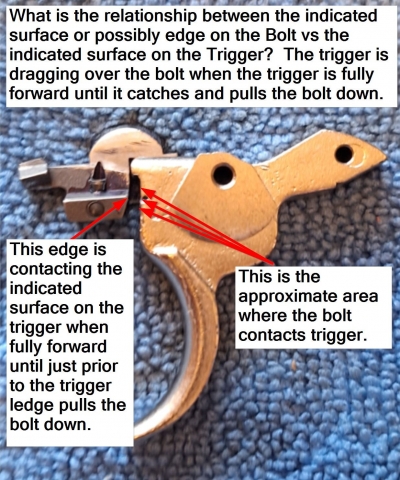

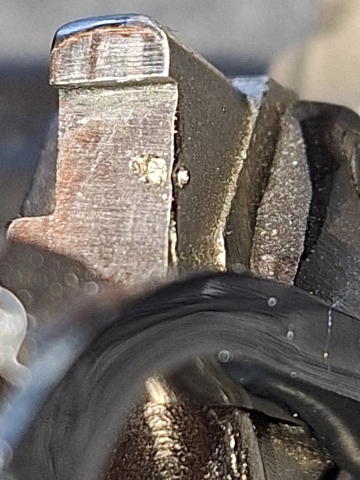

It appears that the rear edge of the Bolt rides against a machined surface on the front of the Trigger. This is the area with a shallow ledge (looks similar to a sear) that catches and retracts the Bolt when the Trigger is pulled in DA firing mode. There appears to be a void in the metal. One hole comes in from the side and breaks through on the left edge of the surface just below the edge that catches the Bolt. The upper edge of the hole has a sharp edge and will sometimes catch my fingernail. I suspect this is the root cause. See attached pictures.

Along with any other input you may have, please help me answer the following:

1. Does the barrel have to be removed in order to remove the cylinder assembly from the frame?

2. What is suggested to remove a very tight barrel nut?

3. Is the tiny plunger, which installs into the Bolt, supposed to be spring loaded such that it pushes proud of the Bolt's side?

4. I'm considering to very lightly debur the edge of that void shown in attached pics. Is this a bad idea or should I go ahead and do this?

Thanks

BS

DWF Supporters

February 8, 2019

Offline

OfflineHere are some pictures of the Bolt. The 3rd picture shows the tiny plunger at it's maximum protrusion. The 4th pic shows the plunger at the depth that spring will push it outward. The plunger presses inward, slightly, and will push back up to this position. Is this normal or should it move to the end of its travel via preload from spring?

I have not taken apart a large frame gun so I am not fully knowledgeable but I can try to answer your questions.

The barrel nut may have been loctited on by a silhouette shooter. The 44 mags held all the IHMSA records in the early 80s. The accuracy of the revolver could be tuned by the tightness of the nut. If that is the case, heating the nut and end of barrel to 350 degrees will soften the loctite. I have never done it myself. You can use a soldering iron or blow torch. Perhaps a hair dryer will expand the nut enough to remove it if it is not loctited. In the future, just tighten the nut snuggly. Do not over tighten anything on a Dan. There is another way to remove the nut using a Threaded rod and nuts on each end but I haven't ever done it. I am sure there are pictorials in Gunbroking about it. Might not work if it is loctited. If you have a plastic tool be aware they can break if you over exert. The metal tools are better. I have seen socket

By all means remove the burr on the bolt. I am not sure it has anything to do with your problem though. I suspect you need a new bolt plunger spring. A very inexpensive fix. The spring is probably the same one as on the small frame gun. EBay is one place to where to find one.

If you have removed the crane lock(the little u shaped piece) the cylinder assembly should slide of the frame when the cylinder is open.

Dans Club

February 24, 2013

Offline

OfflineI had a pistol I bought with a 15” BA and the barrel nut wouldn’t come off. To make things worse, someone boogered up the 2 notches where the barrel nut tool engages the nut. I tried everything everyone on here recommended (soaking in ATF, penetrating oil, heat from soldering gun, heat from hot air gun, steel barrel socket tool from EWK along with threaded rod I wrapped in blue painter tape to protect the barrel), but nothing worked for me. I finally shipped it to Norwich (before Bob the revolver smith retired) and even he couldn’t get it removed without damaging the barrel tube. However, he did save the shroud. It’s still in great condition. I have been searching for a 15” barrel tube for a few years now.

Hope you get it figured out.

DWF Supporters

February 8, 2019

Offline

OfflineThanks for the responses. Since that post, I've ordered the all-steel wrench from EWK along with a new barrel nut. The nut on the barrel is still intact, but it already had a couple of burrs from when it was tightened. I have been soaking the nut with Kroil. The barrel has slots for a compensator, so I'm filling up that cavity and standing up the gun, muzzle down, and letting it soak.

Just to confirm, the barrel does or does not have to be removed in order to remove the Cylinder/Crane assembly? I have removed the Crane Lock and still cannot get the cylinder to move more than an 1/8" or so. Was thinking it might possibly be keyed such that the cylinder had to be rotated to a certain position and that the key position was blocked by the barrel.

Kurt, your picture looks like you have the ultimate pistol pack! Would love to have that! My DW collection is limited to the 44 in this discussion, a 15-2 VH 6", and a 2-tone Kodiak 1911. I set up the 44 with a Redfield scope shortly after I got it and that's the way it's been up until the other day when I disassembled it for the first time.

February 16, 2016

Offline

OfflineBlack Sunshine said

I have been soaking the nut with Kroil. The barrel has slots for a compensator, so I'm filling up that cavity and standing up the gun, muzzle down, and letting it soak.

This is probably your problem. Compensated 44's are notorious for getting carbon build-up inside the shroud.

Dans Club

February 24, 2013

Offline

OfflineBlack Sunshine said

Kurt, your picture looks like you have the ultimate pistol pack! Would love to have that!

Thanks, I love it. The case was made by Stan, a member here of the DWF. He does great work. I’m gonna order another case identical to this one to hold my 7-BA 715 super pac soon.

DWF Supporters

February 8, 2019

Offline

OfflineOle Dog said

Pretty sure there are no slots in the barrel. The barrel is a 4" tube that ends inside the shroud before the slots in the shroud. The barrel but is inside the shroud on the barrel and there is a bushing at the end of the shroud.

I am unable to see any slots in the barrel, thus I don't understand why the shroud is slotted. I still have the original box and it lists the model as a 44v. The shroud is slotted and VH. There is also a box for the barrel. This was purchased through an FFL and I wonder if he did some sort of barrel swap. That was a long time ago and I don't recall the details.

In any case, I'm still soaking in kroil.

WRT the bolt issue, I've stoned some of the surfaces and deburred the void and no improvement. The bolt spring and plunger are fine. With the trigger removed, the bolt moves down and snaps back up, freely. When the trigger is installed, if I push the bolt down, it will not move back up to end of its travel. Also, the bolt is dragging on something when the trigger is installed. The bolt on my 15-2 moves freely with the trigger installed, hammer forward or back. No drag at all.

My next step is to mark surfaces with machinists dye and see if I can get a visual on what is rubbing. I suppose that's an advantage of having a side plate....you can see what's rubbing.

Okay, you don't have a compensated barrel assembly. Disregard everything I said before. You have the standard 44 mag BA with "Power Ports". Not Dan Wesson's finest idea. The gun came with two barrel tubes. One had 6 holes in the muzzle end and one had none. The slots in the shroud are not ports. The gases empty into the space between the barrel and the shroud and then leak through the slots. The barrel with the 6 holes was not to be used with lead bullets, only jacketed bullets. The barrel assembly was supposed to be cleaned after every use. Except for early silhouette shooters, no one used the ported barrel tube. Your shroud and barrel nut may be frozen tougher by lead and unburnt propellant. I would suggest a lead remover but I don't know what it will do to the bluing of the shroud. Once you get it apart clean the inside of the shroud we'll. A 12 guage brass brush will work. And a lot of elbow grease. It may be loctited also. Silhouette shooters would do that when they ascertained the perfect tightness of the nut for accuracy.

Dans Club

March 28, 2023

Offline

OfflineYou need to get a hold of one of these sold by EWK. It's a barrel nut tool with the end that a wrench or socket fits. I had a stuck barrel nut and this aloud Me to put the gun in a vice (using padded foam around gun so no damage is done) then I used a breaker bar with a socket and was able to get the nut off easy.

DWF Supporters

February 8, 2019

Offline

OfflineStmstan 445 said

You need to get a hold of one of these sold by EWK. It's a barrel nut tool with the end that a wrench or socket fits. I had a stuck barrel nut and this aloud Me to put the gun in a vice (using padded foam around gun so no damage is done) then I used a breaker bar with a socket and was able to get the nut off easy.

Thanks, I placed an order for 1ea of the small frame and large frame earlier this week. I went with the T handle version since he was out of the large frame with hex drive. As much as I would cringe from doing so, I could always weld a hex on the T handle if necessary.

DWF Supporters

February 8, 2019

Offline

OfflineThe trigger is rubbing on the bolt when the trigger is fully forward and for a portion of its travel prior to the ledge catching the bolt and pulling it down just prior to the cylinder rotating. If the cylinder is swung open, I can push the bolt down, but it does not move up and down freely. An application of machinist dye showed that the edge of bolt is rubbing on the trigger. My 15-2 feels 100% free and clear of any sort of rubbing.

The diagram illustrates what is rubbing on the trigger and bolt.

My question is, what is the relationship between these to surfaces? Is the area below the trigger'c bolt catch supposed to be clearanced? It seems they should be. If they should have clearance, how much should it have? Is the amount of clearance critical (assuming they should have clearance)?

DWF Supporters

February 8, 2019

Offline

OfflineGot the sticky bolt issue solved. I ended up removing material from the surface on the trigger (see picture in previous post) to the point where I no longer scraped off machinist dye/made contact with the hammer. Now it locks the cylinder without having to touch the hammer or trigger to nudge the bolt closed, The bolt moves freely.

To test, in between intervals of removing material, I needed to install the bolt & cylinder, trigger with hand installed, and then the hammer pin, to bring it all into alignment and proper position.

Disassembly and assembly was straightforward, thanks to the guide on this forum, and a video on YT. I tied the hand and connector together, per the guide and it worked perfectly. Tying them together was a PiTA until I, first, taped them in position with blue painter's tape.

The barrel nut is still stuck, so I'm just going to wait until the all-metal wrench shows up.

Thanks to the folks who responded.

BS

Register

Register Log In

Log In Home

Home