December 9, 2014

Offline

OfflineSo that's my problem. I disassembled after firing some slightly dirty rounds at the range to clean everything. Now I literally can not put back the cylinder assembly properly and it is driving me insane. I have all the parts aligned correctly given the exploded parts view, but now when I try to close it, the extractor is too close to the rear of the frame and will not close (unless you force it, but then it won't function as normal). What exactly is going on here? I have taken it apart and reassembled it many times before.

Has anyone experienced this?

August 29, 2009

Offline

OfflineI'm not sure how the extractor can be too far back such that it hits the frame unless somehow it's not seated all the way in the cylinder or the cylinder is not seated all the way on the crane properly...I'm stumped other than try it again and make sure both the extractor and cylinder are seated all the way on their mating parts.

Dans Club

April 18, 2014

Offline

OfflineDid you pull separate the rod and extractor? Has the bushing been turned the wrong way? Not so likely, but what about alignment sleeve in cylinder face? It has to be something simple if you just cleaned it. Can you account for all your cleaning patches?

Oath Keeper #021479 NRA #206814004

Member AAGSR Member AGA #83120600233

"To preserve liberty, it is essential that the whole body of the people always possess arms and be taught alike, especially when young, how to use them."

Richard Henry Lee

American Statesman, 1788

Supporter

Moderators

January 24, 2009

Offline

OfflineSupporter

Range Officer

Dans Club

Range Officers

Members

July 2, 2011

Offline

Offline

Dans Club

December 5, 2008

Offline

OfflineDecember 9, 2014

Offline

OfflineHappy New Year, everyone. would have got this up sooner but I was busy with the holiday.

I have put all the photos into this album with descriptions. It should load fairly quickly.

I only went to the range once and am getting frustrated, but I believe there is a simple solution. I have tried the bushing oriented both ways, btw. I'm confused

Supporter

Moderators

January 24, 2009

Offline

OfflineDecember 9, 2014

Offline

OfflineTo be diligent, I redid the entire AJT disassembly again and reversed it to reassemble. Still nothing, but I did come up with a test or new configuration to see if I could spot a problem. I installed the crane/extractor assembly without the cylinder onto the frame. The crane swings right into place, and the extractor is well within reach of the cylinder arm, with a little leeway even, and everything functions normally, advancing the extractor.

Since it doesn't work with the cylinder installed, my hunch is I bent the extractor arm at the range. It was harder than I expected so I pushed harder than I expected to... Would that cause the problem I'm having?

Dans Club

DWF Supporters

April 20, 2010

Offline

OfflineHmmm. If you had brass sticking in the cylinders at the range is it possible you bent the ejector star a little bit trying to push the empties out? Like maybe it does not seat into the back of the cylinder properly. I am sure your issue can be figured out, we will get it, its a challenge to solve issues without seeing and holding the actual gun but many issues have been worked thru here on DWF.

"The lion and the tiger may be more powerful, but the Wolf does not perform in the circus"

December 19, 2014

Offline

OfflineHard to tell but it looks like from the 3rd and last pic that the ejector star is not seated completely. Have you tried leaving out the extractor arm, bushing and spring (just slide on the cylinder and the star onto the crane housing) to see if that fits?

While mtwtrf is working through this, is the orientation of the star and the cylinder set at the factory and does it need to be kept consistent (same holes each for cylinder and star)? I'm thinking for timing purposes.

Dans Club

DWF Supporters

April 20, 2010

Offline

OfflineOne other unlikely thought- there is a bushing in the front of the cylinder. It rarely even comes out so it is not an issue, but I have one revolver that the bushing comes out, and it fits properly only one direction, if I flip it around it does not quite seat down into the cylinder right. (see my pics) Your pics show it in the cylinder so I assume you did not have it out so this is unlikely to be your issue. If not then the only thing I can think of is the ejector star not seating all the way in the cylinder face for some reason.

Also be sure the cylinder stop is free to move and not catching the bottom of the cylinder as you close it. Also unlikely but just trying to toss ideas out there.

"The lion and the tiger may be more powerful, but the Wolf does not perform in the circus"

December 9, 2014

Offline

OfflinePaul said

Hard to tell but it looks like from the 3rd and last pic that the ejector star is not seated completely. Have you tried leaving out the extractor arm, bushing and spring (just slide on the cylinder and the star onto the crane housing) to see if that fits?

I believe it is seated correctly, in as far as it in recessed into the cylinder rear, but that doesn't explain the results of your suggestion. I installed the cylinder and crane house alone and there was plenty of movement in there and it could operate normally. When I did as Paul suggested and added the extractor to the mix, I came up with the same problem.

Does this mean it is definitely an extractor problem? Does it rule out the I've bent the crane assembly somewhere? And how the heck would I do that? Seems fairly rugged to me. I'll try to throw up some more pics today.

December 19, 2014

Offline

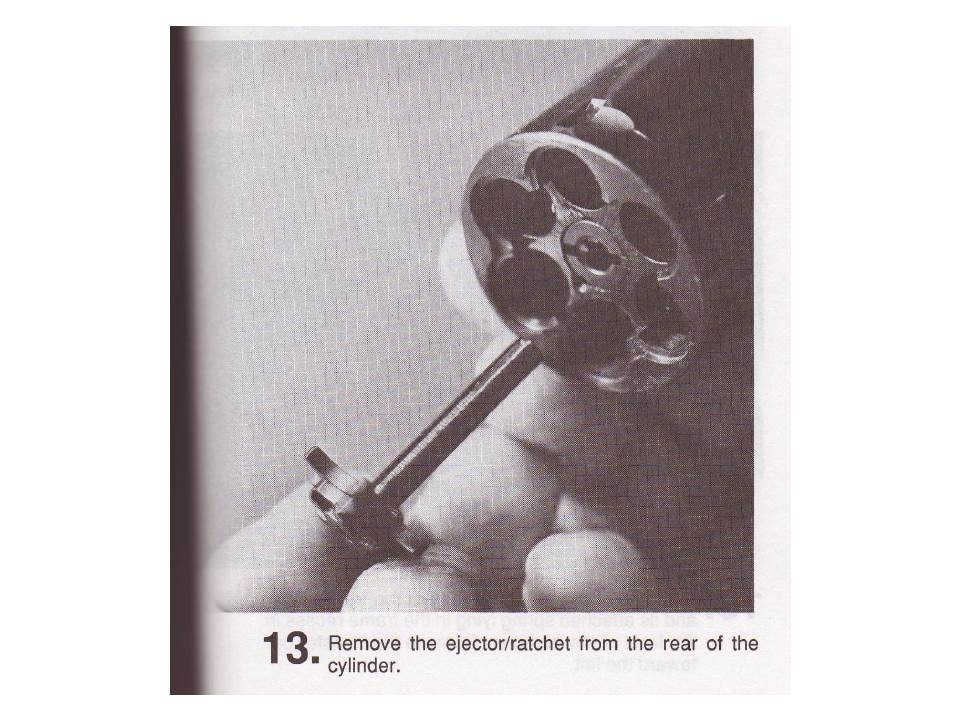

Offlinemtwtrf - not sure if I'm helping just throwing things out, but I guess I'll keep at it until something shows up that helps. Does the back of the cylinder under the extractor look like this pic? Not sure but it looks like maybe there's a bushing threaded in there, maybe it's not seated all the way keeping the extractor from sitting fully flush?

December 9, 2014

Offline

OfflinePaul said

... it looks like maybe there's a bushing threaded in there, maybe it's not seated all the way keeping the extractor from sitting fully flush?

I had that thought as well - perhaps the bit the extractor sits on is threaded. Does anyone know if this is an adjustable piece? I don't want to damage it jamming a screwdriver in there unnecessarily...

December 9, 2014

Offline

OfflineOne more thing I found out - the extractor star is rotating slightly when released from the cylinder.

I uploaded this video to youtube to demonstrate.

It shifts slightly, then shifts back into place as it is retracted.

December 19, 2014

Offline

OfflineI'm would guess that that twist comes from the spring as it's compressed, mine does this a little as well. Are you sure the star is getting seated fully (the nubbings on the back are sitting in the slots all the way (the slots are free of gunk)? The tips of my star sit just a smidgeon below the back face of the cylinder. It looks like yours might be a little high (from the last pic)?

Dans Club

April 18, 2014

Offline

OfflinePaul said

I'm would guess that that twist comes from the spring as it's compressed, mine does this a little as well. Are you sure the star is getting seated fully (the nubbings on the back are sitting in the slots all the way (the slots are free of gunk)? The tips of my star sit just a smidgeon below the back face of the cylinder. It looks like yours might be a little high (from the last pic)?

I agree with Paul on this. I don't think that is a problem as it returns to it's place. The in line angle of the video does not allow the view I would have wanted to look across the face of the cylinder and the star. Make sure the stars trac bushing is down at least flush. I do not know if it is pressed or threaded, tho, it does have a pin. Also, make sure that a rake on the star has not been bent. it may seems extreme but spinning the cylinder hard by hand and also slapping the crane closed of flipping the frame to slam it shut on the fly...I call that cowboy style... can damage the crane and/or cylinder yoke.

Oath Keeper #021479 NRA #206814004

Member AAGSR Member AGA #83120600233

"To preserve liberty, it is essential that the whole body of the people always possess arms and be taught alike, especially when young, how to use them."

Richard Henry Lee

American Statesman, 1788

1 Guest(s)

Register

Register Log In

Log In Home

Home