October 18, 2017

Offline

OfflineVery nice job on the photos. Unfortunately, nothing jumps out to me as being damaged or incorrectly done. A better trained eye than mine is needed, and there are some very knowledgeable members here who may be able to diagnose what is going on with this revolver. The photos are a great help.

October 18, 2017

Offline

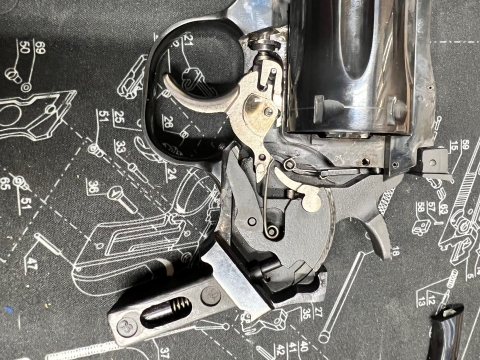

OfflineThe trigger and strut do not appear to match the rest of the action. There should be a small “ledge” on the trigger that the trigger return spring rests on. If the spring slips off that ledge it could wedge itself between the trigger and hand preventing the hand from engaging properly. What I don’t know is if there’s enough clearance for this to occur and still have the side plate seat completely down. Does your trigger have this little ledge?

October 18, 2017

Offline

OfflineDoes this help you? You can clearly see the ledge on the trigger of my early 15-2. I can't see it on your photo, but perhaps you can in person. If it's not there you will need to get a replacement trigger that is for a 15-2. This is the problem with purchasing old DW's; we don't know the complete history, what has been tampered with, replaced etc.

October 18, 2017

Offline

OfflineNo need to shim the cylinder; it appears to be where it should be. You will notice the filed down area on the hand. This is how we custom fit it to the revolver. Sometimes it doesn’t need much, and other times it needs more. Yours appears to have had a good bit removed, and it could be that a previous owner replaced the hand with one purchased online which had been fitted to a different revolver. You could find a new DW hand that has not been filed; then little by little file just enough for proper timing. It’s possible it may need none at all, but that’s unlikely.

October 18, 2017

Offline

OfflineI’ve done the hand fitting on both of my DW’s. It’s tedious work, but well worth the effort. Always remember; you can’t put it back, so be patient and go in little increments. I used a diamond file; the metal is very hard. Good luck with the project and let us know how it turns out.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineI'd clean and put it back together- make sure the spring rides in the groove of the hand, not around it as pictured. That may have prevented the side plate from keeping it in place completely. The hand could have been shifting a bit, causing the timing issue. If not, we'll need pict of the mating surfaces of the hand and star ejector.

Technically, the glass is always full; half liquid, half air....

June 13, 2022

Offline

Offline3ric said

I’ve done the hand fitting on both of my DW’s. It’s tedious work, but well worth the effort. Always remember; you can’t put it back, so be patient and go in little increments. I used a diamond file; the metal is very hard. Good luck with the project and let us know how it turns out.

I might need to IM you if you don't mind.

June 13, 2022

Offline

Offlinerwsem said

I'd clean and put it back together- make sure the spring rides in the groove of the hand, not around it as pictured. That may have prevented the side plate from keeping it in place completely. The hand could have been shifting a bit, causing the timing issue. If not, we'll need pict of the mating surfaces of the hand and star ejector.

The gun was really clean when I started, I plan to clean and replace the spring first. I'm really start to think someone tried to improve the trigger but failed and then sold it.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineI thought the gun was lightly used too considering the lock work condition. And very dry. The Average Joe Tuneup in Gunsmithing will guide you in tuning up the lockwork. I use Flitz on the moving parts and inside frame and sideplate. The lockwork is held in place by the frame and sideplate and rubs so light smoothing makes a big difference. Don't over polish or oil. In my opinion, the very best thing you can do is use the Wolfe reduced power trigger return spring and the 8lb hammerspring. Ron is right about the hand spring not in the slot in the back of the hand. It is unlikely the ratchet and hand are worn much because the gun looks so lightly used. Make sure the frame pins on the right side of the frame are fully seated. Us a rubber, plastic or wood hammer to tap the rivet heads. If they have backed out a little it can cause all kinds of problems.

June 13, 2022

Offline

Offline3ric said

No need to shim the cylinder; it appears to be where it should be. You will notice the filed down area on the hand. This is how we custom fit it to the revolver. Sometimes it doesn’t need much, and other times it needs more. Yours appears to have had a good bit removed, and it could be that a previous owner replaced the hand with one purchased online which had been fitted to a different revolver. You could find a new DW hand that has not been filed; then little by little file just enough for proper timing. It’s possible it may need none at all, but that’s unlikely.

Will the new hand require file fitting? I installed it and just dry firing the timing is way better.

October 18, 2017

Offline

OfflineNot sure, but more concerned about the gap between the frame and side plate. Check for burrs on both surfaces and file if necessary. You’ve said that the gun is clean, but check the tiny corners for caked on debris. If you do find something and get a tighter fit, the hand may start to bind, but hopefully not. Does the timing seem correct now? If so, maybe you don’t need to do anything more to it.

2 Guest(s)

Register

Register Log In

Log In Home

Home