February 25, 2016

Offline

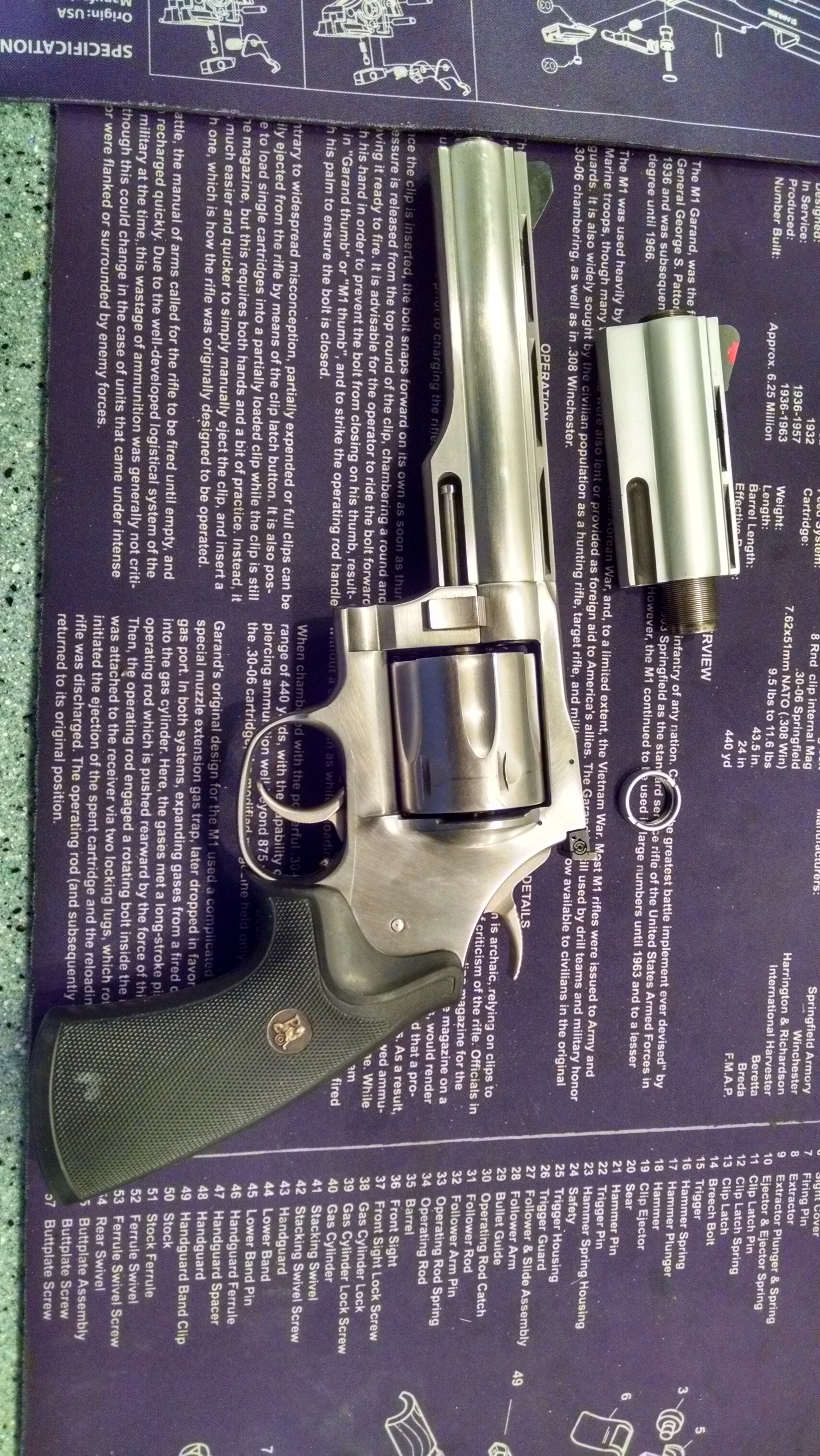

OfflineIf the barrel is sticking out to far for the tool to engage the nut then you're going to have to use a little Cajun ingenuity. Find a socket that'll pass the od of the barrel, but not too far past the id of the barrel shroud. Then you're going to take a grinder and make a deep drive barrel tool once you mark the spots where you need to tie into the barrel nut.

Dans Club

December 5, 2008

Offline

Offline

DWF Supporters

February 1, 2016

Offline

OfflineSnakeInMyBoot said

Remove the barrel nut, then remove the shroud. Screw the barrel into the frame until the gap is .002-.006 then put the shroud back on then reinstall the barrel nut. Should take three minutes.

I would also clean inside shroud and barrel, clean and inspect threads and blow off w/compressed air before

assembly, and .002 shim will be needed if not w/tool

BTW why is gap so much tighter on large frame compared to small frame .006 ?

stop at new members thread and intro self

SIZE DOES MATTER

Hi and welcome. If you can find a way to turn the barrel, maybe a dowel in it, you can unscrew the barrel from the frame. Or as Snake-eye suggested, tap on the slots in the nut. Do you have another nut with the 4" assembly? BTW, that 4 "is worth more than the frame.

. The gap is. 002 on the large frames because the larger cylinders do not expand as they heat up and bind. Also the machining seems to be better and perpendicular. Once you learn the look of the correct gap, whether it is. 006,. O02 or something in between as is the case with most small frames, you can just eyeball the gap by holding it up to the light. After a few cylinders worth of rounds it is a good idea to wipe the face of the cylinder. I usually try to get less than factory spec but don't forget to take the barrel tool with you when shooting.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineTreat it like a stuck nut and barrel. Here's the thread on how to remove it. BTW, please take a moment to stop by the New Members section and introduce yourself. Regards, Ron

Technically, the glass is always full; half liquid, half air....

March 9, 2016

Offline

OfflineSo I tried the dowel trick that Ole Dog suggested and that didn't work. So I passed it off to a friend of mine who is more mechanically inclined than I am. He did what SnakeinmyBoot suggested. He modified a 16mm socket, gave it a little heat and the nut came off. Whoever owned it before used locktite on the nut. I'm not sure the gun has been fired much. We ran both barrels with both .44Spl and .44Mag. It runs great. Because of the holes in the top of both barrel shrouds I thought the 6" would be ported like the 4" is. Why is the ported 4" worth so much? The gun was built in Monson.

Thank you all for your help.

March 22, 2016

Offline

Offlinerwsem said

Treat it like a stuck nut and barrel. Here's the thread on how to remove it. BTW, please take a moment to stop by the New Members section and introduce yourself. Regards, Ron

I agree on the threaded rod and douple nut trick, have done it on numerous pistols for other friends that installed b/a's incorrectly... it works great. When I saw it posted here in a help section, it popped my baloon, because I thought I came up with it when I figured this out back in the early 80's heheheh.

as for the question about ported shrouds and non vented bbl's, as far as I'm aware, all of the ported bbl models actually came with 2 bbls and a shroud, one ported bbl, and one solid, so you could shoot lead.... at least all the ones I bought new came that way... likely the owner that sent you his, lost track of his extra bbl's.

1 Guest(s)

Register

Register Log In

Log In Home

Home