September 24, 2018

Offline

OfflineHi,

I own a Dan Wesson revolver, model 732, .32 Magnum, with a 6″ barrel and I tried to shoot some targets at the range with .32 wadcutter ammo, but without sucess.

From what I read, this DW revolver is very accurate and also has a very good trigger, but unfortunately the impacts are everywhere around the center of the target, and not a shooter problem

For what I see there is a lot of lead in the forcing cone and also on the rear face of the barrel (already cleaned in the photos), also notice lots of debris came from the gap between the cylinder and the barrel, maybe lead debris…

What I think is that the forcing cone was made to accept round nose lead bullets and not flat ones (wadcutter) so maybe I should open a little the forcing cone with a tool like the “11º Brownells Revolver Chamfering Kit”, what do you think?

Any experience with that?

Thanks in advance for any help,

Mike

September 24, 2018

Offline

OfflineStinger said

mc4 said

I own a Dan Wesson revolver, model 32/732The Model 32 is blued and the stainless version is a Model 732. Clean your revolver ...

Sorry for the mistake, already corrected and yes, I did clean the lead inside the forcing cone, but 50 shots after it is leaded again 🙁

May 21, 2018

Offline

OfflineYour problem is almost certainly to do with the size of your wadcutters, or the size of your chamber mouths, not the forcing cone. More than likely they are very undersized, but it could be an oversize problem too. The best thing to do is measure your chamber mouths with a set of pin gauges. Also use a round fishing weight and slug your barrel. I usually slug mine at both ends, so that I'll know the difference between the forcing cone and the barrel itself. The forcing cone should be just a smidge bigger.

As for the measuring of the chamber mouths, the best example I can give is Ruger 45 cal revolvers. For whatever reason, Ruger has a habit of shipping 45 cal guns out with very undersized chamber mouths. I've heard of some that measure down in the .448-.449 range, when they should be running .452-.454. There is a really good explanation of this on Marshall Stanton's website. He makes and sells Beartooth Bullets. There are links there to the Cast Boolit forum, and a loading database.

If your gun is running undersized chamber mouths, you'd be having pretty much the problems you describe. The undersized mouths result in a bullet getting "shaved" and then "rattling" down the bore, and accuracy goes straight in the crapper. Same thing with a very undersized cast bullet. Your bullet should be .001-.002 larger than the bore diameter (this is why you need to slug your bore). Not all guns will run the same chamber/bore sizes.

For instance, I have three 45-70 rifles. One Chiappa 1886, one Pedersoli Rolling Block, and one Marlin 1895 GBL. The bore on the Marlin runs a little over .458, so the correct cast bullet size is .460 for that rifle. The two Italian guns, on the other hand, are both right at .457(+about another .0005), so the right size for them is .459. Not a problem once I figured this out, but running the .460 sized bullets through the Italian guns resulted in accuracy that dropped off badly after the first 50-60 rounds, with leading getting worse every shot thereafter.

Getting my bullets sized correctly for the gun I'm shooting corrected the problem completely. You wouldn't think that .001" is a big deal, but it can make a huge difference when running cast bullets.

If the chambers measure too small, the solution is to have a smithy hone them out to the correct size, if the slugs tell you that your cast bullets are too small, the answer is a new sizing die, or new mold (if you're casting your own), or a new bullet supplier, (if your going with store-bought).

Hope this helps....

Blessed is he, whom when confronted with death, thinks only of his front sight...

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineI think you're experiencing gas cutting... The throat of each chamber of the cylinder should be about .311"-.312" the bore about .310"

Use cast bullets at .312" or maybe gas checked bullets to see if that clears things up. Set your gap ~ .003"- .004" on the most proud chamber.

Regards, Ron

Technically, the glass is always full; half liquid, half air....

September 24, 2018

Offline

OfflineJonny V said

... If your gun is running undersized chamber mouths, you'd be having pretty much the problems you describe. The undersized mouths result in a bullet getting "shaved" and then "rattling" down the bore, and accuracy goes straight in the crapper. Same thing with a very undersized cast bullet. Your bullet should be .001-.002 larger than the bore diameter (this is why you need to slug your bore). Not all guns will run the same chamber/bore sizes.

If the chambers measure too small, the solution is to have a smithy hone them out to the correct size, if the slugs tell you that your cast bullets are too small, the answer is a new sizing die, or new mold (if you're casting your own), or a new bullet supplier, (if your going with store-bought).

Hope this helps....

I tried to measure with a digital micrometer and this is what I get:

Cylinder mouth: 0.310

Forcing cone entry: 0.325

Bullet: not sure, but website states 0.314

Front barrel: 0.302,

I don't have round fishing lead, instead I have round lead balls .36 for cap & ball revolver (MLAIC), it is a little bigger than the .32, do you think I can use it inside the chambers and the barrel, or could it be too big and need too much force to pass through?

September 24, 2018

Offline

Offlinerwsem said

I think you're experiencing gas cutting... The throat of each chamber of the cylinder should be about .311"-.312" the bore about .310"Use cast bullets at .312" or maybe gas checked bullets to see if that clears things up. Set your gap ~ .003"- .004" on the most proud chamber.

Regards, Ron

As I said above, I measure 0.310 in the cylinder and 0.302 in the bore (not inside the grooves). I do not reload my ammo, only can buy some commercial ones, usually Fiocchi...

May 21, 2018

Offline

Offlinemc4 said

I tried to measure with a digital micrometer and this is what I get:

Cylinder mouth: 0.310

Forcing cone entry: 0.325

Bullet: not sure, but website states 0.314

Front barrel: 0.302,

I don't have round fishing lead, instead I have round lead balls .36 for cap & ball revolver (MLAIC), it is a little bigger than the .32, do you think I can use it inside the chambers and the barrel, or could it be too big and need too much force to pass through?

Yes those round balls would work great. Use a brass hammer to tap them down into the cylinder, then a piece of oak dowel to push them all the way through, measure with a good micrometer, a caliper is not as accurate. Obviously, you need to support the cylinder in something like a soft-jaw vice for this, and put a towel down on the floor to catch the slug when it falls. The barrel should be straight forward, I just hold mine in my hand on the bench top and tap the round ball in there with the brass hammer. It's easy to do.

You need to do your barrel for sure, but going by your numbers above, I bet this is your problem. The barrel should be in the neighborhood of .310 (as rwsem states), but it could be a little bigger too (.311?). If you are shooting a .314 bullet through there, then it's getting shaved pretty bad, and that's where your lead (all over the barrel face and forcing cone) is coming from. In any case, a .310 chamber mouth is pretty tight. Verify this number with 6 round ball slugs (each chamber) and if it's true, you might look at having them honed out by a smithy. It shouldn't be too expensive, and it's not as uncommon as you would think. Ruger's been shipping 45 revolvers in this condition for years.

If your barrel slugs at .312, then the correct size cast bullet would be .313-.314. If it's at .310-.311, then that .314 bullet is too big and you're getting a similar situation as what I had going on with my 45-70 rifles.

Blessed is he, whom when confronted with death, thinks only of his front sight...

September 24, 2018

Offline

Offline

Guys,

Guys,

After reading your answers and viewing some videos, I came to the conclusion that I have a very bad and problematic Dan Wesson 732 revolver and maybe without or difficult repair 🙁

In the end I have two problems:

Timing problem (slow) and misalignment cylinder/barrel problem...

Now I see why I have a lot of lead debris coming from the gap cylinder/barrel and lot of lead on the top of the barrel (no photo) and in the forcing cone. When I push the hammer back, the barrel rotates but sometimes do not engage in the cylinder stop, so I shot many rounds with the cylinder chambers a little to the left of the barrel, where the lead accumulates...

On the other hand even with the cylinder docked in the cylinder stop - I do not have a light to put inside the chambers - if I introduce a brass rod inside the barrel it touches the left side (viewing from front) of the cylinder, in all the chambers, what do not happen on the top, right and bottom of the barrel...

So, I have a slow timing revolver and a misalignment cylinder/barrel 🙁

About the misalignment I don't think I can do anything unless open a little the forcing cone, am I correct?

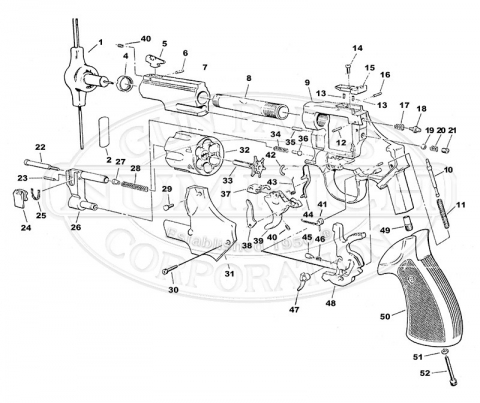

Now, regarding the timing, I notice that the hand has a recess near the tip, where it touches the ratchet in the cylinder, I don't know if that recess is from factory or is wear - the revolver is like new, only a total of maybe 400 or 500 shots - but I think that is the problem, as it turns when in reaches the middle of the ratchet it doesn't touch it anymore so the movement is not enough to turn until it reaches the cylinder stop...

Must I buy a new hand? Can I adjust mine?

Anyway, I passed some lead balls through the cylinder and barrel and got the following measures:

Barrel (front)= 0.3120

Barrel (back) = 0.3125

Barrel (inside groove) = 0.3005

Cylinder throat = 0.3135

.32 S&W LWC Bullet = 0.314 (from Lapua website, not sure about Fiocchi)

Thanks in advance for any help.

Mike

Dans Club

December 5, 2008

Offline

Offline

Dans Club

December 5, 2008

Offline

OfflineFebruary 16, 2016

Offline

Offlinemc4 said

In the end I have two problems: Timing problem (slow) and misalignment cylinder/barrel problem...

I recommend that you return your firearm to the Dan Wesson factory, to have their expert gunsmiths repair and time the revolver. When I was sending in a gun to them, Bob Collins told me;

"If you are interested in sending in your gun for work, please go to the link below and enter your information. You will then be emailed a conformation letter with the RMA # for your case. Please include this # on your package. Also include a letter stating what you want done and add all of your contact info. Then send it in any way you want. We will contact you for payment, soon after the gun arrives."

September 24, 2018

Offline

OfflineStinger said

I recommend that you return your firearm to the Dan Wesson factory, to have their expert gunsmiths repair and time the revolver. When I was sending in a gun to them, Bob Collins told me;

"If you are interested in sending in your gun for work, please go to the link below and enter your information. You will then be emailed a conformation letter with the RMA # for your case. Please include this # on your package. Also include a letter stating what you want done and add all of your contact info. Then send it in any way you want. We will contact you for payment, soon after the gun arrives."

Thanks, that was my first thought, the problem is that I am in Portugal, West Europe, very far from the USA factory and the costs and the legal papers make it unfeasible 🙁

I bought the revolver new, maybe in 1995 or so, as a defense weapon, so in 23 years I only shot 15 or 20 rounds, and notice the lead debris but thought it was normal...

Now that I tried to use it in target competition I noticed the leaded barrel, the no accuracy... and that a long time ago I bought a very bad revolver 🙁

May 21, 2018

Offline

OfflineThat would certainly cause your problems! Your barrel cylinder slug numbers look real good so it’s definitely not that. You need a competent gunsmith to look that revolver over. Timing issues are generally beyond the scope of a DIY repair.

Blessed is he, whom when confronted with death, thinks only of his front sight...

Just maybe I have a solution. I have taken apart , cleaned and reassembled very many small frame Dans. I have built from parts and bare frames several guns. I have used used cylinder assemblies and used hands. In my experience, every used hand I have put in have timed perfectly. 357 and 22 lr. They are identical and interchangable regarding caliber. I know they are a factory fitted part but every one I have used has worked fine. Maybe they use a jig when fitting them and MOSTLY get it the same every time. I think there is a better chance of a used hand fitting than a new, unfiled hand. The metal is very hard and the part very small. I doubt I could ever fit one properly. So, my suggestion is to acquire a used hand on eBay or from a forum member. Do you know someone in the States that can ship you one? I estimate the cost would be under $ 40 plus shipping to Portugal.

Is your hand blue? All the stainless guns I have worked on have had stainless hands. Perhaps your hand is not original.

October 18, 2017

Offline

OfflineReplacing the hand with another used one is most likely what is needed, but looking at the photo the hand looks fine, and the fact that so few rounds have been fired through this revolver leads me to question excessive wear. There is another odd possibility, and something that Ole Dog and I have discussed on a different post that concerns the roll pin that holds the rear cylinder bushing in place. You can see it when you push the ejector rod all the way in as it's right under the ratchet star. If this pin happens to be missing, that would allow the cylinder to be out of time with the ratchet thereby causing the misalignment. Not likely, but something to check.

September 24, 2018

Offline

Offline3ric said

Replacing the hand with another used one is most likely what is needed, but looking at the photo the hand looks fine, and the fact that so few rounds have been fired through this revolver leads me to question excessive wear. There is another odd possibility, and something that Ole Dog and I have discussed on a different post that concerns the roll pin that holds the rear cylinder bushing in place. You can see it when you push the ejector rod all the way in as it's right under the ratchet star. If this pin happens to be missing, that would allow the cylinder to be out of time with the ratchet thereby causing the misalignment. Not likely, but something to check.

Thanks for your input and sorry but don't understand wich is

Thanks

1 Guest(s)

Register

Register Log In

Log In Home

Home