September 24, 2018

Offline

OfflineHi again,

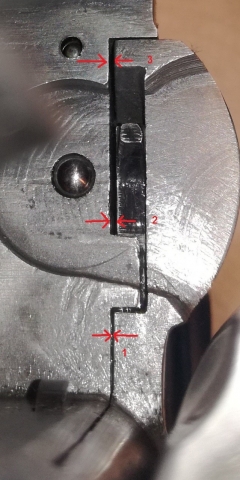

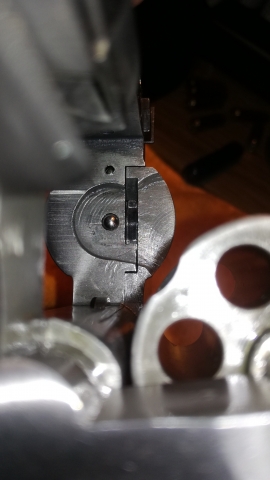

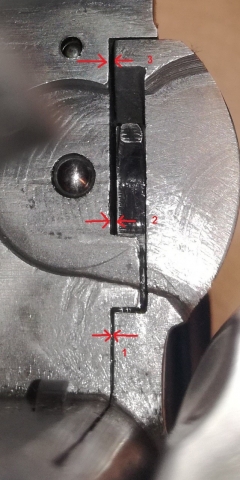

I discovered something else, responsible for the slow timing - there is a huge gap between the left side cover frame and the mainframe, exactly where the hand moves up and down and that gap moves away the hand from the cylinder (2)

If we see, the bottom part of the side cover (1) is tight but the upper part (3)is very far away.

In the movie bellow we can see the lateral movement of the hand (2) 🙁

https://vimeo.com/user89990635/review/292133302/0373cc86ed

I have the two Allen screws very tight, I think that I even used too much force as I slightly damage the head of the screws, so can´t see what to do more to reduce the gap.

I find very difficult to fit in the left side frame, it seems to bee bigger than the free space, maybe I need to sand a little the top part which fits near the rear sight ...

Any thoughts?

September 24, 2018

Offline

OfflineAndrew1220 said

I would still reach out to Bob at DW (bob@cz-usa.com) and explain your situation and the fact that you live in Portugal, include photos etc. See if he thinks replacing the hand with a used one might work? Maybe he has some other advice?

Hi Andrew, thank you for your help. Please send him too my last photo, with the gap between the main frame and the left side frame, to see what he says about it.

As I bought the revolver new and this is a problem since I start shooting with it, maybe part of the problem (slow timing) could be a left side frame poorly machined. Now about the misalignment cylinder /barrel, it must be another thing, although it may be minimized if the cylinder rotates until it fits in the cylinder stop... maybe this minimum misalignment that I can feel with a brass rod could not even be a problem ... don't really know

Best regards from Portugal

Mike

October 18, 2017

Offline

OfflineThis drawing only shows the cylinder as a complete unit (32 on the drawing). What it doesn't show is the front and rear bushings separately. My post concerns this rear bushing which is at the heart of the timing of the cylinder on a swing out revolver. The groove cut in the shaft of the extractor (ratchet) mates with a protrusion inside this bushing. This bushing is very precisely fit in the exact position to align the ratchet with the bolt cuts on the cylinder. The roll pin fits into a tiny hole drilled simultaneously into the bushing and the cylinder and serves to maintain this exact alignment. If this tiny roll pin should ever come out then we're relying on just a friction fit of the bushing inside the cylinder for the timing rather than the roll pin actually turning the cylinder to its lock up position. It's an easy thing to check if the roll pin is in place; just look under the star ratchet and you'll see the bushing and pin I've spoken about. There should only be a needle sized hole which is the center of the roll pin. If there is a larger hole (approximately 1/16th inch) then the roll pin is missing. If the roll pin is missing then the hand is now turning the ratchet (and of course the cylinder) to whatever position the friction fit of the bushing will allow. If it comes up a little short as you've been describing, then the bullet will "shave" itself into the forcing cone thereby causing the extreme leading. Check for that pin. If it's there, then this problem has to be a hand/ratchet issue; qualified gunsmith territory for sure.

October 18, 2017

Offline

OfflineWow, that last photo really tells the tale. That gap should certainly not be there, and since the hand relies on the side plate opening to lock the cylinder in place, that could easily be the whole problem with this revolver. Look for whatever machining burrs is causing the side plate not to seat properly, remove them, and you problem just might be solved! Good luck!

Oboy, that is undoubtedly the problem. The sideplate holds everything together and working properly. Some slide on easily, but some can be bears to get back on. The trigger return spring will sometimes be knocked off the little ledge of the trigger where it rests and prevents the sideplate from fitting right. That usually results in trigger problems though. Make sure the the hammer and trigger are fully seated against the frame. It is very hard for me to fit a sideplate on a blue gun. A stainless gun is a little softer metal. Are the edges of the sideplate where it joins the frame raised or flush with the frame. If raised, then I believe you can fix it by a little judicious filing. Do not use a round dremel type tool. Use a flat fine stone . If the sideplate is flush against the frame I think it came from the factory that way. When replacing the sideplate do not hammer it around the long narrow part. They can be weak there.

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineLooks like it's been taken apart before and the side plate wasn't seated properly. I recommend taking it apart, thoroughly clean it, then put it back together, paying particular attention to getting everything seated where it should be.

Technically, the glass is always full; half liquid, half air....

September 24, 2018

Offline

OfflineNew input:

As many of you said, the side plate is the problem, it is not tight with the frame so the hand moves freely to the side and doesn't move the cylinder all the way around.

So last night I disassembled all the parts, tried to fit the side plate alone, but had the same problem, so I sand its flat surfaces and underneath and after that it fits almost correctly, a little gap on the upper side, but the hand is more secure, almost no lateral movements and now the timing is correct. When I put back the hammer first the cylinder stops in the cylinder stop and only after that the hammer stops in position...

So, maybe I have to take it all again and do a deeper polish, to see if the side plate goes in a little more and then I need to go to the range to see if it shots better, it has to do it 😉

Thanks for all your help,

Mike

1 Guest(s)

Register

Register Log In

Log In Home

Home