September 3, 2010

Offline

OfflineHello All,

I am having a bit of a problem withthe barrel (or at least shroud) of my 744 coming loose and wiggling when I shoot it.

A little background information, when I got the revolver, it had the original factory barrel nut. I took it to the range a few times, and it fired spectacularly (in fact, everyon that has ever pulled the trigger has fallen in love with it). No problems, no hiccups, nothing. Perfect performance every time. Then, I lost the barrel nut when detail cleaning it after a few range trips (I know, it was a dumb thing to do, but I couldn't finish it in one day, and lost when I stored it). So, I ordered a new barrel nut from CZ. After it arrived, and I completed cleaning and assembly, and I took the pistol to the range. After a few shots I noticed taht I felt the barrel shroud wiggling; so I tightened it up. After having to repeat this a few times, I realized that I potentially had a problem; possibly a very dangerous one. So, I figured my two choices were to either come here and see if I could figure out a solution to my problem, or take it to a gunsmith; and since was (by far) the cheaper of the two options, I decided to come here and give it a shot.

Now, my questions are, is this a situation/problem anyone else has run in to before? Is it at all common? Is it a problem specifically with the newer barrel nuts from CZ specifically? Anyone have a potential solution/fix to this problem? Thanks in advance for your time, and any information or answers you might have.

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

Offline to the forum! Look to the right of the screen at EWKarms, he makes by far, the best parts for Dan Wesson revolvers. I have some of his barrel nuts and they are superior to the factory Dan Wesson nuts. I don't know why you are having difficulty with the nut from CZ but I think Eric can help you . Get one of his barrel tools also.

to the forum! Look to the right of the screen at EWKarms, he makes by far, the best parts for Dan Wesson revolvers. I have some of his barrel nuts and they are superior to the factory Dan Wesson nuts. I don't know why you are having difficulty with the nut from CZ but I think Eric can help you . Get one of his barrel tools also.

BTW, where was your gun made? IE Monson, Palmer or Norwich.

Just curious.

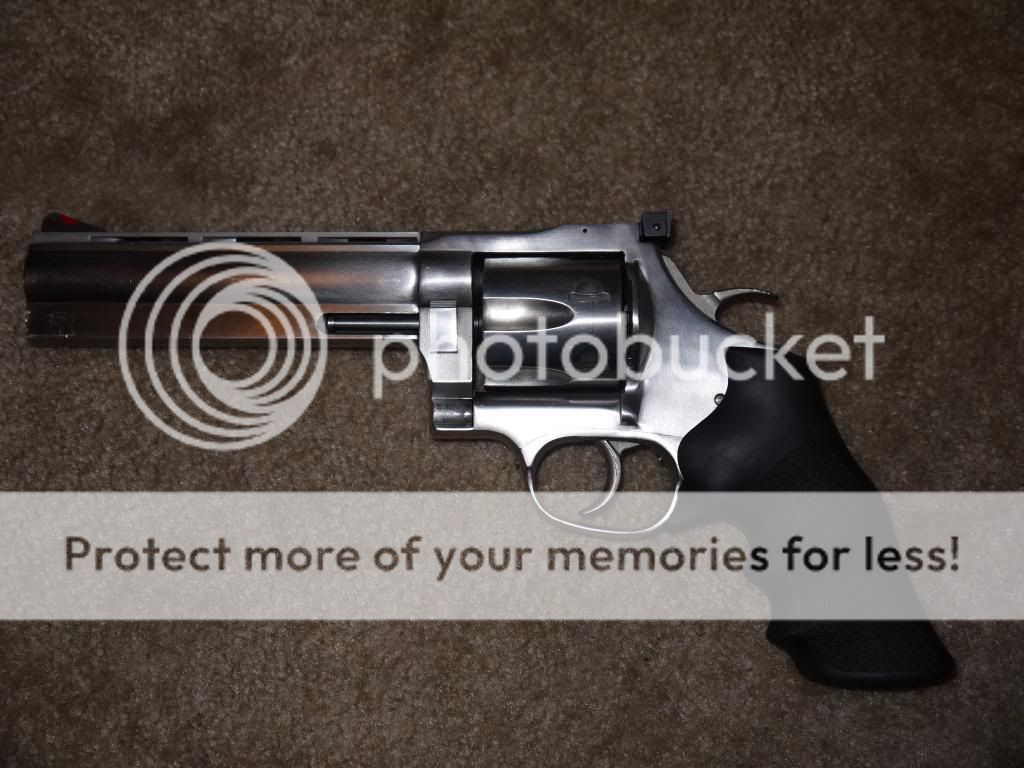

We like pics so post some  of your 744.

of your 744.

Anything worth doing is worth doing well.

My father

If a man designed it, and a man built it, then a man can fix it.

My grandfather

September 3, 2010

Offline

OfflineIt has Monson, Mass. stamped above the serial number, and below Dan Wesson Arms on the side of the frame. Don't know if that denotes where it was made or not. The serial number is in the 44S0026XX range if that gives any useful info at all. If not, I can try to hunt down the original box in my garage somewhere and see if I can find any info on it there. I do know that my dad has had it since I can remember though (before he gave it to me). Give me a minute for some pics. Also, thanks for the heads up on EWK, I will give them a look here directly.

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

OfflineMay 3, 2011

Offline

OfflineI have never heard of a nut problem like that before. Some of these guys probably have. Most people complain about not being able to get them off. I know they can work loose sometimes. Are you putting a lot of rounds through it? That frame has a pin that sticks into the shroud to keep it from turning. Is it there? Are you using excessively powerful loads? I would order EWK barrel nuts. It always good to have some spare ones. What ever you do don't loctite it. I'm wondering if that shroud is fitting the frame perfect or not. There can be a lot of variables. Let us know how it works out?

Dans Club

March 2, 2008

Offline

OfflineI'm afraid I won't be much help on the cause or solution, but I owned a 744 and had a similar problem. I found I had to really crank down on the barrel nut or the barrel actually started backing out of the frame. I don't like to over tighten barrel nuts, so I just made sure to check regularly, and I let the barrel threads in the frame "dirty up" a little. The extra friction on the threads seemed to hold things in place better.

I went to a bookstore and asked the saleswoman "Were is the Self Help Section?" She said if she told me, it would defeat the purpose.

George Carlin

September 3, 2010

Offline

OfflineGary J said

I have never heard of a nut problem like that before. Some of these guys probably have. Most people complain about not being able to get them off. I know they can work loose sometimes. Are you putting a lot of rounds through it? That frame has a pin that sticks into the shroud to keep it from turning. Is it there? Are you using excessively powerful loads? I would order EWK barrel nuts. It always good to have some spare ones. What ever you do don't loctite it. I'm wondering if that shroud is fitting the frame perfect or not. There can be a lot of variables. Let us know how it works out?

I did have a problem with the barrel shroud sticking before (my dad liked to put lead reloads through it, so it kinda gunked up), I just had to heat it up a little, and I got it off with a little muscle power. I actually didn't put a lot of rounds through it. I had just put a couple cylinders through it when it started loosening. Seemed like every other cylinder, I had to re-tighten it. All-in-all, I put less than 50 rounds through it that day. I usually didn't put many rounds through it at a time, and I don't think my father did either. It is a wonderful firearm, just not one I would put 400-500 rounds through at a time. Last I checked, the shroud-to-frame pin was there; even with it loose, I still can't rotate the shroud around on the barrel, so I am assuming it still is. I will double-check. I am only using Winchester white box (240 gr. SJSP, 1,180 fps.) and Remington UMC (180 gr. JSP, 1,610 fps.) loads. The hand loads my father used (I inherited a few of them) actually seemed really kind of light to me compared to WWB and RUMC. Although, I have been told that DW's can handle heavier loads, as they are typically built more stoutly than other firearms (although, maybe not as stoutly as the Ruger Super Hawks). I really don't know how hot a load would have to be to warrant being "excessively powerful" for a DW. I had actually thought (although very briefly) about loctiting it, but I knew DW's were well known for getting stuck barrels; so I promptly put a stop to that idea, and decided to check here before I did. I think I will try the EWK rout first, and see how it works. I'll update y'all after I get a chance to try it out.

September 3, 2010

Offline

OfflineSteve CT said

I'm afraid I won't be much help on the cause or solution, but I owned a 744 and had a similar problem. I found I had to really crank down on the barrel nut or the barrel actually started backing out of the frame. I don't like to over tighten barrel nuts, so I just made sure to check regularly, and I let the barrel threads in the frame "dirty up" a little. The extra friction on the threads seemed to hold things in place better.

Overtightening of the barrel is something I have been a bit wary of myself. I was also worried about not breaking the barrel nut tool, as I had not idea they were replacable or that anyone made aftermarket units. Now that I know, it may be a little different story.

September 3, 2010

Offline

OfflineAlright my friends, I have spectacular news. Last night, I gave the pilstol a good cleaning; pulled the barrel shroud off, pulled the barrel out, scrubbed inside and out of both. Gave the receiver and cylinder a good scrubbing as well. Dried everything really well, and oiled the moving parts. Made sure that the barrel, barrel nut, shroud, and all threads were clean and dry. I then set the barrel using the barrel gap feeler gague, and threaded the barrel nut on. I tightened down the barrel nut just as tight as it would go on under normal force. I then gave the nut just a little bit moore "oomph", and it seated just a little more.

I am happy to report, that my friend and I, put 50 rounds down range today without a single issue. The barrel shroud is still set tight and firm. I think I must say that I think our friend Steve CT was correct, and I just neede to give it a little more to get it just a bit tighter. All-in-all, I think the problem is solved, I am ecstatic, and the revolver performed spectacularly (as always). I am again once again, one very pleased owner of a Dan Wesson 744 HV8C. Now, I need to find a good holster for it so I can use it as my backwoods gun again.

Once again, thank all of you for your help and information. I doubt that, without all of you, I probably would have ended up spending a bunch of money at a gunsmith's shop, for essentially nothing. Looking around this site for the answer to this problem has given me a lot more information about my DW than I started out for, and has made me love it even more. Thanks for providing such a great community.

September 3, 2010

Offline

OfflineSteve CT said

If you are using a plastic DW Barrel Wrench, please get an EWK Barrel Wrench and save yourself much agony down the road.

I absolutely plan on getting the EWK Barrel Wrench and barrel nuts for starters. I also plan on browsing everything else they make; as I feel that an 8" barrel, and possibly even a 10" barrel, would make this a great pig hunting gun.

September 3, 2010

Offline

Offlinerobhof said

Are you oiling the threads on the barrel? They should be dry for shooting to give that extra grip, clean and oil for storage, but wipe dry with alcahol before firing.

No, I don't thread the barrel or barrel nut on wet. I knew that would happen if I did. As I do with all of my other guns, I wipe a very thin layer of CLP on them for corrosion protection, then wipe it off until it is completely dry. That is typically how I store them as well, periodically repeating the process (sans disassembly) to ensure corrosion protection. I really feel it was a case of simply not being torqued on properly, as I was afraid of getting the barrel nut stuck. Lesson learned, it's no good preventing the barrel nut from sticking by under torquing it, if you can't use the pistol anyways because the barrel nut keeps working loose.

September 3, 2010

Offline

OfflineKoneistaja said

I did have same problem with shroud. Try this: Put shroud in freezer in 12 hours, then put it together. Even normal nut will hold it tighly.

That would only be a temporary fix. Once the shroud warmed back up, thermal expansion would kick back in, and the problem would be back. Shooting the pistol would make it heat up and expand even more, compounding the problem further.

April 28, 2011

Offline

Offlineoni.dori said

Koneistaja said

I did have same problem with shroud. Try this: Put shroud in freezer in 12 hours, then put it together. Even normal nut will hold it tighly.That would only be a temporary fix. Once the shroud warmed back up, thermal expansion would kick back in, and the problem would be back. Shooting the pistol would make it heat up and expand even more, compounding the problem further.

When shroud heating up, it`s just pushing barrel nut harder. If shroud is hot, you can`t even open barrel nut. Almost same kind idea, when you using cold crimp.

1 Guest(s)

Register

Register Log In

Log In Home

Home