July 4, 2020

Offline

OfflineHi, I'm new to the group, coming from Barstow, Commiefornia (don't hold it against me, I intend to escape this place).

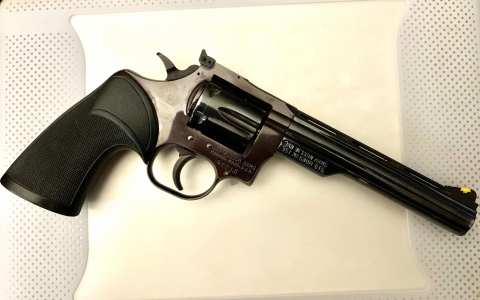

I have a similar gun that I can't seem to find a definitive model number on. It appears to be an older one as the serial number is 92216, and it's marked as a 357 Magnum CTG, from Monson, Mass. I have an issue with the cylinder that you can rotate by grabbing it and turning it (doesn't look like the video loaded). It doesn't catch solidly. Also, the barrel may be out of alignment with the cylinder as it got knocked on the left-hand side. I'd be interested in sending it in to Dan Wesson/CZ to fix, but I'd like to at least get the model number before doing so, to see if they can at least fix it. It's more of a sentimental gun than anything, knowing that the cost is probably going to be more than it's worth. It was my first handgun that I bought.

Thanks in advance for your input!

Mike

July 4, 2020

Offline

OfflineThank you very much for the advice Ole Dog! I really appreciate it. I recently tore it down to clean it based upon a YouTube video. I have the tools for it, including the feeler gauge, so I just need to get the parts then. Another fix project I have is a Remington Model 51. That should prove challenging, LOL!

Mike

July 4, 2020

Offline

OfflineAll, I'm wondering if I need a new cylinder based upon some wear I'm seeing from where the cylinder latch sets in the cylinder (see photos, sorry for the poor quality, my phone does not have a macro mode). Opinions? I'm still looking at replacing the springs as suggested by Ole Dog as I'm sure they're weakened, but further looking at my cylinder makes me wonder if there's a secondary problem that wasn't evident in the previous post. Please let me know your thoughts on this. Thanks! Mike

May 1, 2020

Offline

OfflineIt doesn't appear that there is anything wrong with your cylinder the ring is from the cylinder lock.and it is normal for any revolver that is cocked multiple times to get this cylinder ring. I don't see anything wrong with the cylinder notches. As I said it appears to be normal wear to me.

Nobody

Dans Club

December 5, 2008

Offline

OfflineYes, normal. As a matter of fact, it is in nice shape. DW calls that the bolt. Smith calls it a cylinder block. Slides out of the bottom strap to catch the cylinder at lock up. Colt Pythons don't contact the cylinder until the scalloped part is there. Hence they don't show the cylinder line unless the gun is out of time. Smiths and DW do drag along the cylinder as it turns. I have read that a light file stroke on the leading edge of the bolt/cylinder block when the gun is new will remove the very sharp edge that causes the line. I would be afraid of causing a timing or lock up problem. Some folk put a little black tape on the cylinder to protect the finish. Most Revolvers have the line when leaving the factory from test firing and checking the timing.

July 4, 2020

Offline

OfflineThank you all for the input. I wasn't too concerned about the line, as you indicated, it's just wear. I was more concerned about the notches for the block, or bolt. That's where there's more wear than anywhere on the gun. I know that it didn't come out too well in the photos, but if this is normal, I will replace the springs. It just seems strange to me that I can rotate the cylinder while it's in the gun and the hammer dropped. I will continue the rest of the cleaning (I couldn't remember how to get the hammer spring out when I cleaned it, so the hammer didn't come out either, but now I know). I appreciate all the info and will also see about lightly polishing it on the inside, keeping in mind that the Monson guns are only hardened on the surface per some posts.

Your knowledge is much appreciated and I will be glad to have this gun back in service!

Again, thanks!

Mike

July 4, 2020

Offline

OfflineWell, I've put in the new springs, and did a little polishing on the inside. I have to say, there is minimal pull on the trigger in SA, but I can still grab the cylinder and spin it when the hammer is down, almost to the point that it freely spins (once you get it started it's real easy). I don't use force when doing it. When cocked, it seems to lock better, but on some cylinders there's some movement that can be made. I don't have this with any other revolvers, and am afraid I may need to get a cylinder for it (but can't find one). Any additional thoughts?

Thanks for all you input!

October 17, 2017

Offline

OfflineI've taken a very close look at your photo in post 7. It appears that the cylinder is riding too far back in the frame, and the bolt is not centered with the cylinder bolt cuts. This may be causing the bolt to only be able to grab a small portion of the cylinder cuts which could be causing the unusual cylinder turning you're describing. The real question is why this is happening. One possible explanation: when you are setting the barrel/cylinder gap are you holding the cylinder to the rear most position? I hope not!! The detent ball should be holding the cylinder to the front as you set the gap. There would be considerable dragging of the front of the cylinder against the forcing cone of the barrel (provided the spring loaded detent ball is functioning properly) if the gap was set with the cylinder held back. I'm wondering if the spring behind the detent ball is either broken or missing altogether thus allowing the cylinder to be so far back in the frame.

Dans Club

December 5, 2008

Offline

OfflineThe aligning ball (dedent ball) screw may be too loose. It generally should be screwed in to where it is flush with the frame in order to put enough forward pressure on the cylinder. This is very important to proper function. The aligning ball spring may be weak or there may be crud built up around it. I think that bad alignment could cause the peening issue you have seen. Did you replace this spring with the others?

You could also check the bolt spring, bolt plunger set up to be sure they are properly pushing the bolt into position. Also determine if the bolt has been modified, such as by filing, etc..

Also make sure the crane lock is correctly installed.

If you do all these things and still suspect the cylinder. I can probably find one to loan you to determine if that really is the problem.

July 4, 2020

Offline

OfflineThank you all for the replies. You've given me more things to think about and to check. I'll see about looking into these issues. When I put in the springs, it did not include the detent ball spring, as that was not part of the kit I bought, and the crane lock I was sure to put in correctly, but I can certainly double-check without any concerns. As for the gap between the barrel and cylinder, I checked it, but if the detent spring is bad, or the screw is not in properly, that would impact the actual gap, so definitely something to check.

3ric, I see what you mean regarding the mark on the cylinder. If I'm not mistaken, the wear line should be centered with the notches cut for the cylinder lock. Good eye!

Again, thanks all! Much appreciated!

1 Guest(s)

Register

Register Log In

Log In Home

Home