August 8, 2016

Offline

OfflineUh oh!! Well that’s not good...![]()

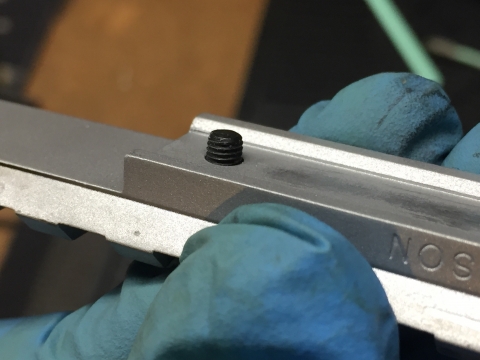

I thought just the scope base screws came loose but two of the three screws sheered in half!

[Image Can Not Be Found]

[Image Can Not Be Found]

[Image Can Not Be Found]

That scope base has seen 1500+ rounds since I got it in February 2019, so it held up for a little while. I guess my reloads were a wee bit too stout....

I’m hoping the screws can easily be removed from the shroud. Dan Wesson is closed otherwise I’d just ship it to their revolversmith and have them fix it. But it doesn’t seem like it should be that difficult for a machinist?

Maybe just use an easy out tool? Going to bring it to my local gunsmith this week see if they can get the screws out then I’ll just have to try to find new screws. Also hoping the threads aren’t junk.

It would be nice if I could prevent them from breaking again. I almost wonder if they started loosening up and I continued shooting which broke them?

Shit I thought I’d break the scope before the scope base or the screws...

October 1, 2012

Offline

OfflineAndrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Supporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineMost likely 8-40 but might be 6-48. I see part of the problem; at least one mounting hole has no bottom. Drilling mounting holes and attaching scope bases is a precision job, if done correctly. A good gunsmith will use a screw, longer than needed, and file it so the screw will bottom out and secure the mount with the correct amount of torque. Hobbyists will use screws short enough to not bottom out and call it good.

Technically, the glass is always full; half liquid, half air....

August 8, 2016

Offline

Offlinerwsem said

Most likely 8-40 but might be 6-48. I see part of the problem; at least one mounting hole has no bottom. Drilling mounting holes and attaching scope bases is a precision job, if done correctly. A good gunsmith will use a screw, longer than needed, and file it so the screw will bottom out and secure the mount with the correct amount of torque. Hobbyists will use screws short enough to not bottom out and call it good.

I determined them to be 6-48 1/4" screws.

This was drilled and tapped by Bob at DW. The holes go all the way through the shroud. But I agree that the screws should be longer.

1/2" is too long but 3/8" would be perfect. However Brownells was sold out of the 3/8" so I settled on the 1/4". I didn’t have any loctite that I could recall and I think the screws loosened up during shooting which then didn’t take much to torque on them and snap?

i was able to get the second screw out using my fingernail and nylon punch. So just one more to go!

I dropped off the shroud with my local smith and he’s confident they’ll get it out. He said if the threads are damaged he’ll install a helicoil insert in the threads.

I’m also going to use some loctite (blue) underneath the scope base to add a little bit of strength. And of course going to blue loctite on the threads.

And good call on the proper amount of torque. I just guesstimated and probably overtightened the screws. I bought a torque wrench in amazon to measure the torque. Looks like 18 lbs is what is recommended for 6-48 screws.

August 8, 2016

Offline

Offlinehugelk said

Andrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Thanks. I wish I could do that but the last remaining screw is below flush which makes it next to impossible to do that.

Its with my local smith now. He hopes to have it out this weekend (busy guy).

May 3, 2011

Offline

OfflineAndrew1220 said

hugelk said

Andrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Thanks. I wish I could do that but the last remaining screw is below flush which makes it next to impossible to do that.

Its with my local smith now. He hopes to have it out this weekend (busy guy).

There is always EWK, if he can't repair it nobody can. Its hard to find DW scope mounts at a reasonable price.

August 8, 2016

Offline

OfflineGary J said

Andrew1220 said

hugelk said

Andrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Thanks. I wish I could do that but the last remaining screw is below flush which makes it next to impossible to do that.

Its with my local smith now. He hopes to have it out this weekend (busy guy).

There is always EWK, if he can't repair it nobody can. Its hard to find DW scope mounts at a reasonable price.

I agree EWK is plenty capable but I doubt he has the time to do it.

The drill and tap scope bases that I have from DW are readily available from them. Cost is $49 plus tax and shipping. I got 3 of them. One on my 722, 715, and 744.

May 3, 2011

Offline

OfflineAndrew1220 said

Gary J said

Andrew1220 said

hugelk said

Andrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Thanks. I wish I could do that but the last remaining screw is below flush which makes it next to impossible to do that.

Its with my local smith now. He hopes to have it out this weekend (busy guy).

There is always EWK, if he can't repair it nobody can. Its hard to find DW scope mounts at a reasonable price.

I agree EWK is plenty capable but I doubt he has the time to do it.

The drill and tap scope bases that I have from DW are readily available from them. Cost is $49 plus tax and shipping. I got 3 of them. One on my 722, 715, and 744.

Thats a good price. The other DW mounts are 200.00 plus. At one time it was 20.00 to drill/tap one screw. Your mounts came from CZ DW?

August 8, 2016

Offline

OfflineGary J said

Andrew1220 said

Gary J said

Andrew1220 said

hugelk said

Andrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Thanks. I wish I could do that but the last remaining screw is below flush which makes it next to impossible to do that.

Its with my local smith now. He hopes to have it out this weekend (busy guy).

There is always EWK, if he can't repair it nobody can. Its hard to find DW scope mounts at a reasonable price.

I agree EWK is plenty capable but I doubt he has the time to do it.

The drill and tap scope bases that I have from DW are readily available from them. Cost is $49 plus tax and shipping. I got 3 of them. One on my 722, 715, and 744.

Thats a good price. The other DW mounts are 200.00 plus. At one time it was 20.00 to drill/tap one screw. Your mounts came from CZ DW?

Bob charged me $40 to drill and tap the 3 holes. Yup these mounts came from CZ/DW. I had my local gunsmith cerakote them in a stainless “color” to match the rest of the gun. Yes I love stainless 😂. The 722 in the bottom pic was before I had Bob do the silhouette slots and laser engraving.

May 3, 2011

Offline

OfflineAndrew1220 said

Gary J said

Andrew1220 said

Gary J said

Andrew1220 said

hugelk said

Andrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Thanks. I wish I could do that but the last remaining screw is below flush which makes it next to impossible to do that.

Its with my local smith now. He hopes to have it out this weekend (busy guy).

There is always EWK, if he can't repair it nobody can. Its hard to find DW scope mounts at a reasonable price.

I agree EWK is plenty capable but I doubt he has the time to do it.

The drill and tap scope bases that I have from DW are readily available from them. Cost is $49 plus tax and shipping. I got 3 of them. One on my 722, 715, and 744.

Thats a good price. The other DW mounts are 200.00 plus. At one time it was 20.00 to drill/tap one screw. Your mounts came from CZ DW?

Bob charged me $40 to drill and tap the 3 holes. Yup these mounts came from CZ/DW. I had my local gunsmith cerakote them in a stainless “color” to match the rest of the gun. Yes I love stainless 😂. The 722 in the bottom pic was before I had Bob do the silhouette slots and laser engraving.

Those are some awesome looking revolvers. Bob has to be an awesome gunsmith. You can't hardly find any really good gunsmiths anymore. If you do they live several 100 miles away. I had a friend that was a great machinist. He had a gun store and he could make anything. If he couldn't find a part he would make it.

August 8, 2016

Offline

OfflineGary J said

Andrew1220 said

Gary J said

Andrew1220 said

Gary J said

Andrew1220 said

hugelk said

Andrew, The screws should come out fairly easy. There is no longer any compressive force on the threads which is what causes the torque. I bought a shroud that had broken screws and removed them by cutting a light notch in the exposed portion. I used a very small diamond cutting wheel on my Dremel. Then removed with flat blade screwdriver. My ACE hardware has a nice bin full of various size Gunsmith fasteners. I for get the size but they had ones that have been working great. Good Luck

Thanks. I wish I could do that but the last remaining screw is below flush which makes it next to impossible to do that.

Its with my local smith now. He hopes to have it out this weekend (busy guy).

There is always EWK, if he can't repair it nobody can. Its hard to find DW scope mounts at a reasonable price.

I agree EWK is plenty capable but I doubt he has the time to do it.

The drill and tap scope bases that I have from DW are readily available from them. Cost is $49 plus tax and shipping. I got 3 of them. One on my 722, 715, and 744.

Thats a good price. The other DW mounts are 200.00 plus. At one time it was 20.00 to drill/tap one screw. Your mounts came from CZ DW?

Bob charged me $40 to drill and tap the 3 holes. Yup these mounts came from CZ/DW. I had my local gunsmith cerakote them in a stainless “color” to match the rest of the gun. Yes I love stainless 😂. The 722 in the bottom pic was before I had Bob do the silhouette slots and laser engraving.

Those are some awesome looking revolvers. Bob has to be an awesome gunsmith. You can't hardly find any really good gunsmiths anymore. If you do they live several 100 miles away. I had a friend that was a great machinist. He had a gun store and he could make anything. If he couldn't find a part he would make it.

Thanks! Ya he does amazing work! He’s refinished a few of my shrouds too. Couple of which he didn’t charge me for. Probably because I give them so much business.

Well my gunsmith was able to get the last screw out, without damaging the threads! Only cost me $20. So pumped.

August 8, 2016

Offline

OfflineTorque wrench and loctite arrived today.

Last week I cleaned the screws, shroud and scope base with gun scrubber then acetone and let them dry for days. They should be squeaky clean and dry.

I added some loctite under the base and on top of the shroud and on the screws. Torqued to 20 inch pounds. Handy little tool.

Then I’ll let it cure for a couple days before I bring it back to the range.

1 Guest(s)

Register

Register Log In

Log In Home

Home